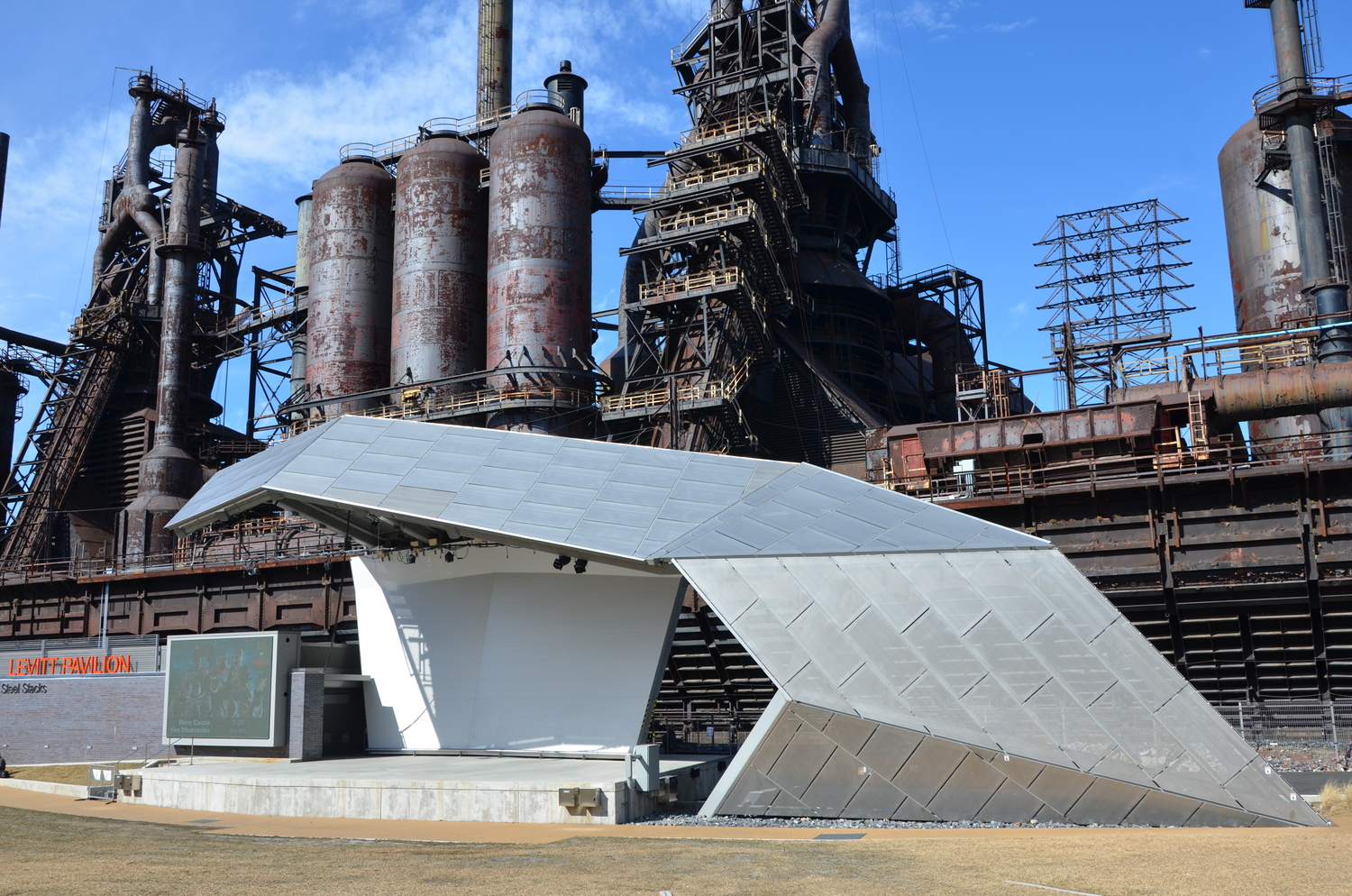

Bethlehem, PA

Levitt Pavilion SteelStacks

Scope/Solutions

With the historical Bethlehem Steel plant as a backdrop, the Levitt Pavilion is a tribute to the industry’s past and a symbol of revitalization. Envisioned by architect Wallace Roberts & Todd as a complex faceted architectural form, the pavilion required innovative structural engineering expertise. SGH’s analytic and collaborative approach helped the project team deliver the project ahead of schedule and on budget.

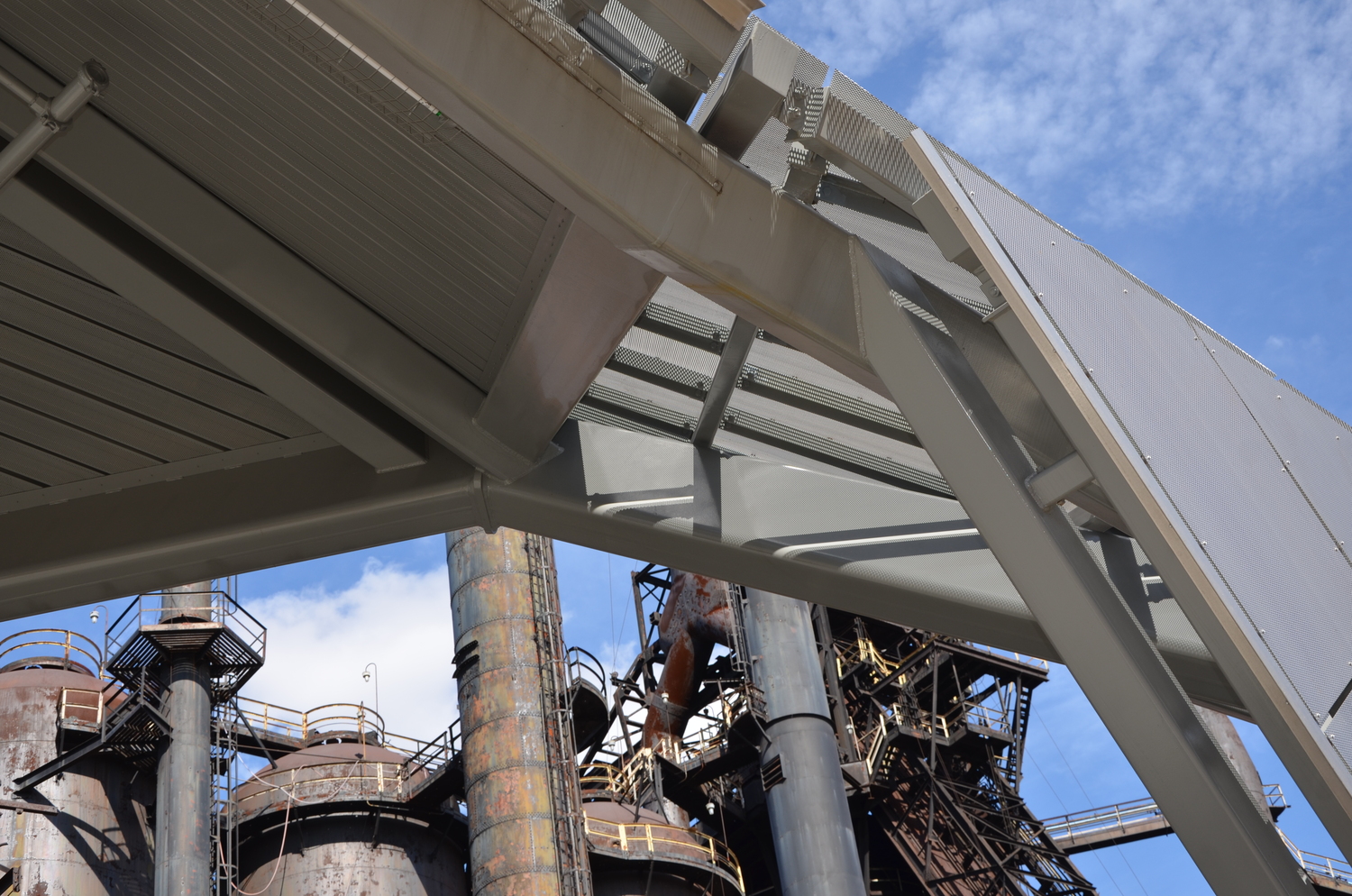

The concert venue features an exposed structural steel frame clad with a skin of perforated stainless steel panels. Its distinctive geometry rises 37 ft and cantilevers 35 ft forward to shelter the stage. The surface then twists, falling forward and stage left.

To ensure that the structure would reflect the architect’s vision and to develop the structural integrity of the pavilion, SGH completed the following:

- Designed the primary structure, including six supporting ribs to achieve a uniform deflection at the cantilevered edge

- Designed a secondary steel system for the stainless steel panels, using repetitive sizes and connections for ease of fabrication

- Coordinated the design, including the overall geometry, member shape and location, and connection detailing

- Created three-dimensional models of the systems and used building integration modeling, saving documentation and shop drawing time

- Collaborated with the contractor and steel fabricator to incorporate their preferences into the design

- Worked daily with the design team during construction to facilitate execution and expedite shop drawing review

Project Summary

Key team members