Bronx, NY

Unionport Bridge

Scope/Solutions

During construction of an approach span to a new bascule bridge, New York City Department of Transportation questioned the finishing procedures and long-term durability of the concrete bridge deck. Working for the construction team, SGH evaluated the concrete finish and materials to determine if the in-place materials satisfied the project specification requirements.

SGH evaluated the concrete and developed recommendations to enhance the expected durability of the concrete. Highlights of our work include:

- Reviewing the New York City Department of Transportation specifications for high‑performance concrete, which was required for the new deck

- Using ground penetrating radar to identify locations where core sampling would not impact the embedded reinforcing steel

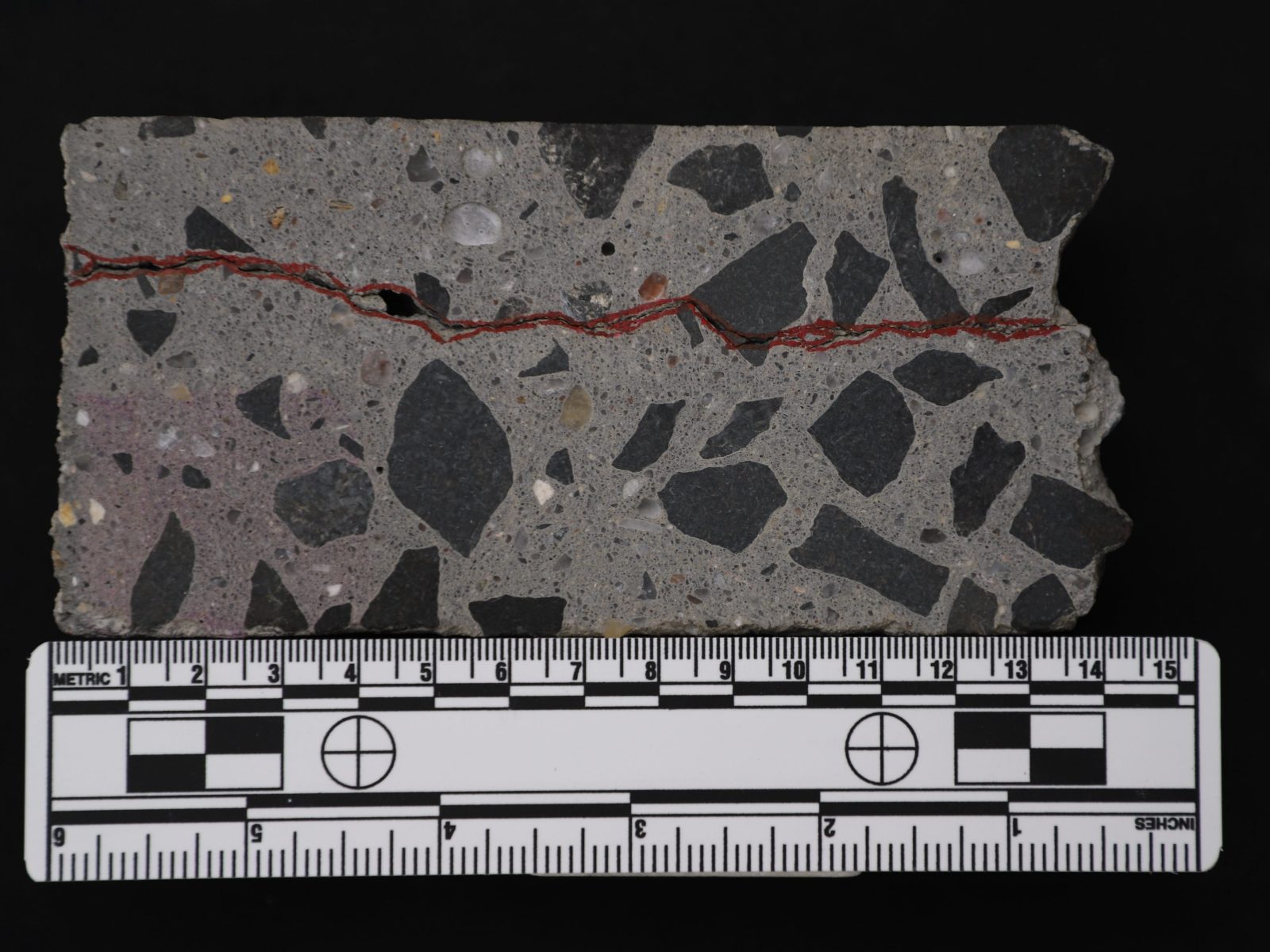

- Measuring surface crack widths and depths at extracted core samples

- Performing testing in our laboratory to evaluate the concrete’s chloride ion permeability per ASTM C1202

- Recommending the contractor apply a methyl methacrylate sealer to the approach span to reduce permeability

- Collaborating with the construction team to coordinate the bridge deck tining with the sealer installation

Project Summary

Solutions

Evaluation

Services

Structures | Applied Science & Research

Markets

Infrastructure & Transportation

Client(s)

Unionport Constructors, JV

Specialized Capabilities

Repair & Strengthening | Materials Science

Key team members

Nathaniel Smith

Managing Principal, Structural Engineering, New York

Additional Projects

Northeast

MassBiologics, Stormwater Retention System

Following partial collapse of the chambers in 2006, SGH investigated the cause of failure and recommended remedial action. We subsequently provided consulting services for redesigning and installing a replacement system.

Northeast

Stop & Shop

Shop & Stop Store #505 is a one-story building constructed with a rooftop parking deck. SGH evaluated the condition of the traffic coating, the roof structure, and the exterior building walls, which were also covered with a failing elastomeric coating.