Texas

Filtered Water Tank

Scope/Solutions

The 40 ft dia. filtered water tank at a nuclear power plant was leaking. After assessing the steel tanks’s condition, the plant operator identified interior corrosion, small holes, and areas with steel section loss, and decided to undertake a project to repair the deterioration. SGH supported the design-build contractor for the remedial work by designing carbon fiber-reinforced polymer (CFRP) repairs.

SGH designed a watertight CFRP liner for the floor and bottom 2 ft of the tank, and a corrosion protection CFRP laminate for the tank wall. Highlights of our work include:

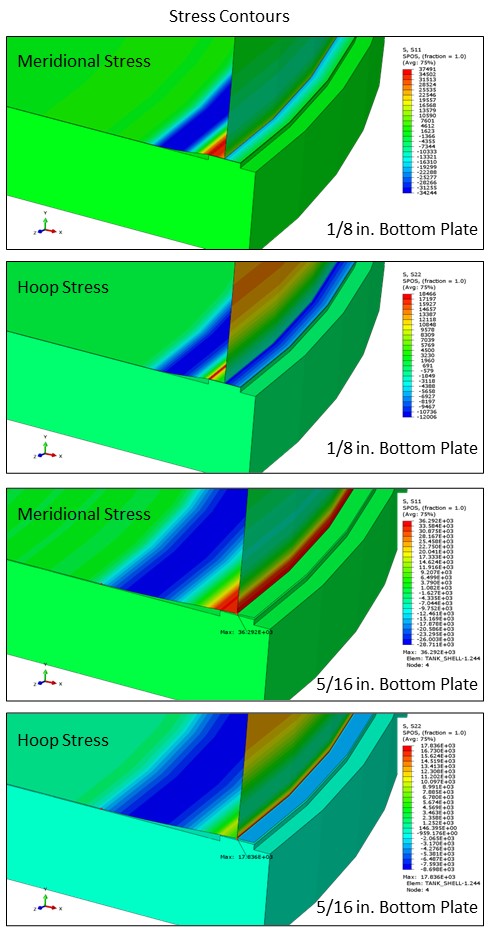

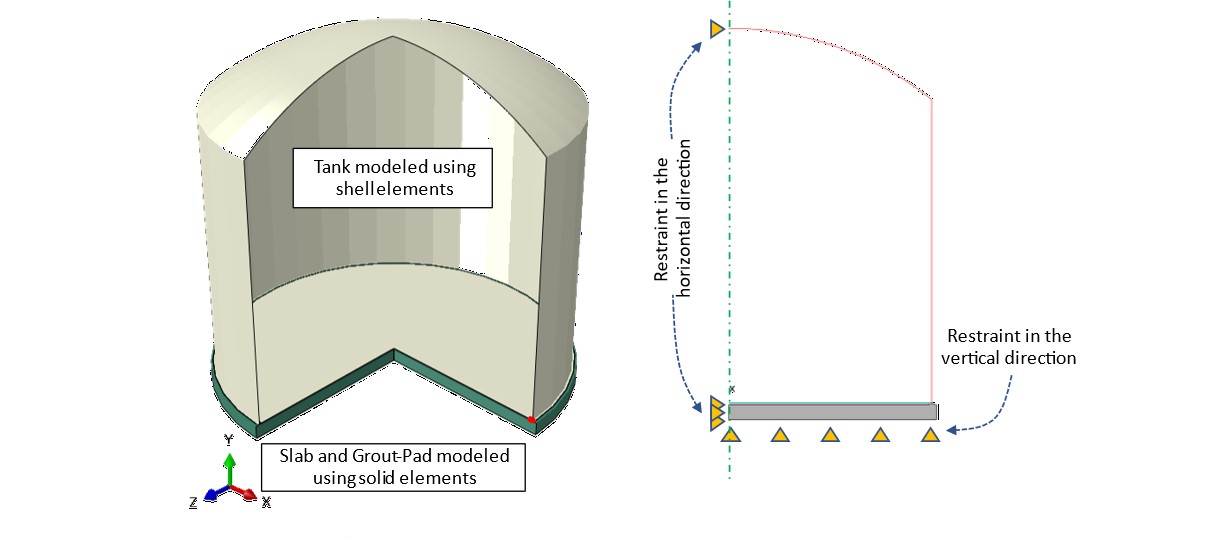

- Performing finite element analyses to determine the stresses and strains in the steel tank considering:

- Steel section loss due to corrosion

- A loss of support if the 1 in. layer of sand between the tank floor and concrete foundation washes away

- Developing CFRP repairs based on the AWWA Standard C305

- Preparing design drawings and specifications for the CFRP repair work

- Submitting calculations documenting our design and the associated assumptions

Project Summary

Solutions

Repair & Rehabilitation

Services

Advanced Analysis | Structures

Markets

Energy

Client(s)

Structural Technologies LLC

Specialized Capabilities

Repair & Strengthening | Nuclear | Computational Mechanics

Key team members

Additional Projects

South

Lake Livingston Hydroelectric Plant

East Texas Electric Cooperative (ETEC) commissioned construction of a new hydroelectric plant at the site of the fifty-year-old Lake Livingston Dam, an approximately 2.5 mi earthen embankment that impounds a water supply reservoir. The project included constructing an intake structure at the embankment, three reinforced concrete penstocks, and a powerhouse on the downstream side of the existing spillway and along the Trinity River. SGH provided engineering services during construction of the hydroelectric plant and continues to serve as the chief dam safety engineer, as required by the Federal Energy Regulatory Commission (FERC).

South

Comanche Peak Nuclear Power Plant, Units 3 & 4

SGH designed Seismic Category I structures at the Comanche Peak nuclear facility for preparation of Combined Operating License Application. SGH analyzed the original structural configuration and seismic input, and reanalyzed and designed them four years later with revised geometry and loading.