Drainage Investigations of Artificial Turf Field Systems

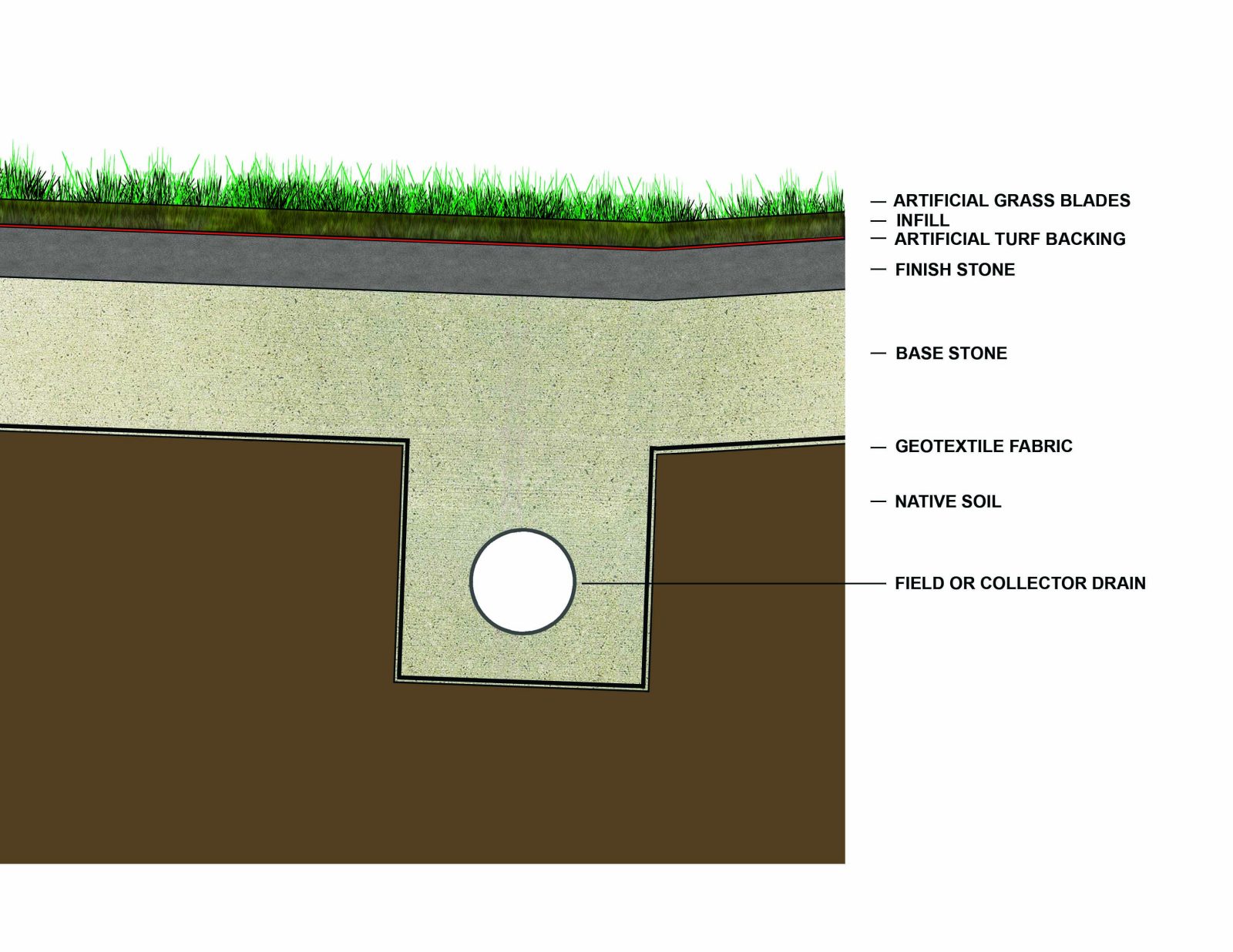

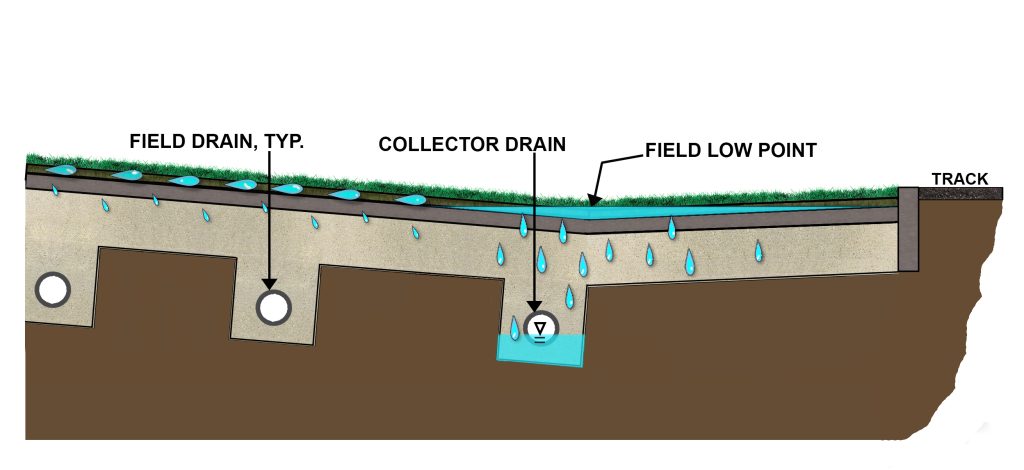

Artificial turf fields are expensive investments requiring careful design and construction to avoid drainage problems. These fields typically consist of a synthetic turf surface over a base coarse layer, with a system of field drains leading to a perimeter collector drain tied into the site’s existing storm drainage piping system. The turf usually consists of synthetic fibers woven into a geotextile backing with drainage slots or holes, and rubber and/or sand infill.

As with many structures, understanding issues with design, construction, and material performance for artificial turf fields can help inform investigations and repair design when these systems do not perform as expected.

Common Improper Design and Construction Practices

- Base coarse gradation and fines content: Deviations in the base coarse gradation and fines content can affect permeability and field drainage. It is important to determine the proper gradation and consider how handling, placement, and compaction can influence the fines content when specifying materials and testing procedures.

- Field and grading design: Artificial turf fields typically have a uniform low point around their perimeter. However, sloping to discrete low points requires the water to infiltrate through the field over a much smaller area and can lead to ponding. Additionally, runoff from adjacent landscaping, walkways, and surrounding tracks can carry fines onto the field surface and promote clogging of the geotextile backing or its drainage holes.

- Permeability and infiltration: The infiltration rate (a measure of flow through the surface) of an artificial turf field should not be confused with its permeability rate (a measure of flow through a specimen based on a given hydraulic gradient across its thickness). The infiltration rate directly influences the duration and depth of ponding. At fully saturated conditions, the infiltration rate equals the permeability rate and is dependent on several variables, including depth of ponded water, material permeability, degree of saturation, etc.

- Geotextile fabric placement: Geotextile fabrics are frequently placed over collector or field drain trenches, but their location needs to be carefully selected. Fabrics placed perpendicular to the direction of flow can impede drainage as they collect fine particles.

Artificial turf field drainage elements

Insufficient Material Performance

- Vertical infiltration: Historically, artificial turf systems relied on ASTM F1551 infiltration tests to evaluate the capacity of flat carpet-style systems without infill. The industry now generally recognizes that these results are not representative for infill systems. The flow during testing primarily leaks horizontally through the infill materials rather than vertically through the turf backing system, giving a false indication of the infiltration rate.

- Unsaturated and transient conditions: Typical analysis and design methods assume a fully saturated condition for all materials in the turf system using estimated field or laboratory measurements, but a field is typically not fully saturated at the onset of a rainfall event. The unsaturated permeability of the infill, artificial turf backing, base coarse, and geotextile fabric will be much lower than the saturated permeability due to air in each element’s void space, initially reducing the volume of water flowing through the field system. To reach the saturated state, air trapped in the void space must escape. Also, air permeability of soil or geotextile fabric is much lower in the saturated state, and in some instances this leads to restriction of air flow, air bubble formation, and ponding issues.

- Internal stability of infill: If the gradation of the turf infill and the size of the turf drainage holes do not prevent the infill from moving into the drainage holes, they can become clogged and reduce the turf’s permeability.

As with many structures, understanding issues with design, construction, and material performance for artificial turf fields can help inform investigations and repair design when these systems do not perform as expected.

Investigation Techniques

Investigators employ several methods to diagnose artificial turf drainage issues. Test pits allow inspection of as-built conditions of the turf and drainage systems, determination of material density and moisture content, and sample collection for laboratory testing. Laboratory testing of the moisture content; grain size distribution; and material permeability and field infiltration testing of the turf geotextile, rubber and sand turf infill, and base coarse materials below the playing surface are useful to determine actual material behavior under saturated or partially saturated conditions. Internal camera surveys of the field, collector, and storm drains help confirm the integrity and performance of these interconnected elements of the field drainage system.

Analysis Methods

Finite element analyses can model transient rainfall, runoff, and infiltration into the artificial turf system, starting in the initial unsaturated state. These complex analyses can evaluate how trapped air escapes and rainwater enters the initially unsaturated void space, replacing the entrapped air until saturation occurs. These transient analyses can estimate any air pressure build-up within the base coarse below the turf with variations in rainfall and storm duration. Separate dynamic flow analyses of the field, perimeter, and storm drains can show the hydraulic impacts that the existing storm drain system may have on the field drainage piping performance.