Building Enclosure Commissioning (BECx): A Strategic Advantage for Obtaining Project Goals

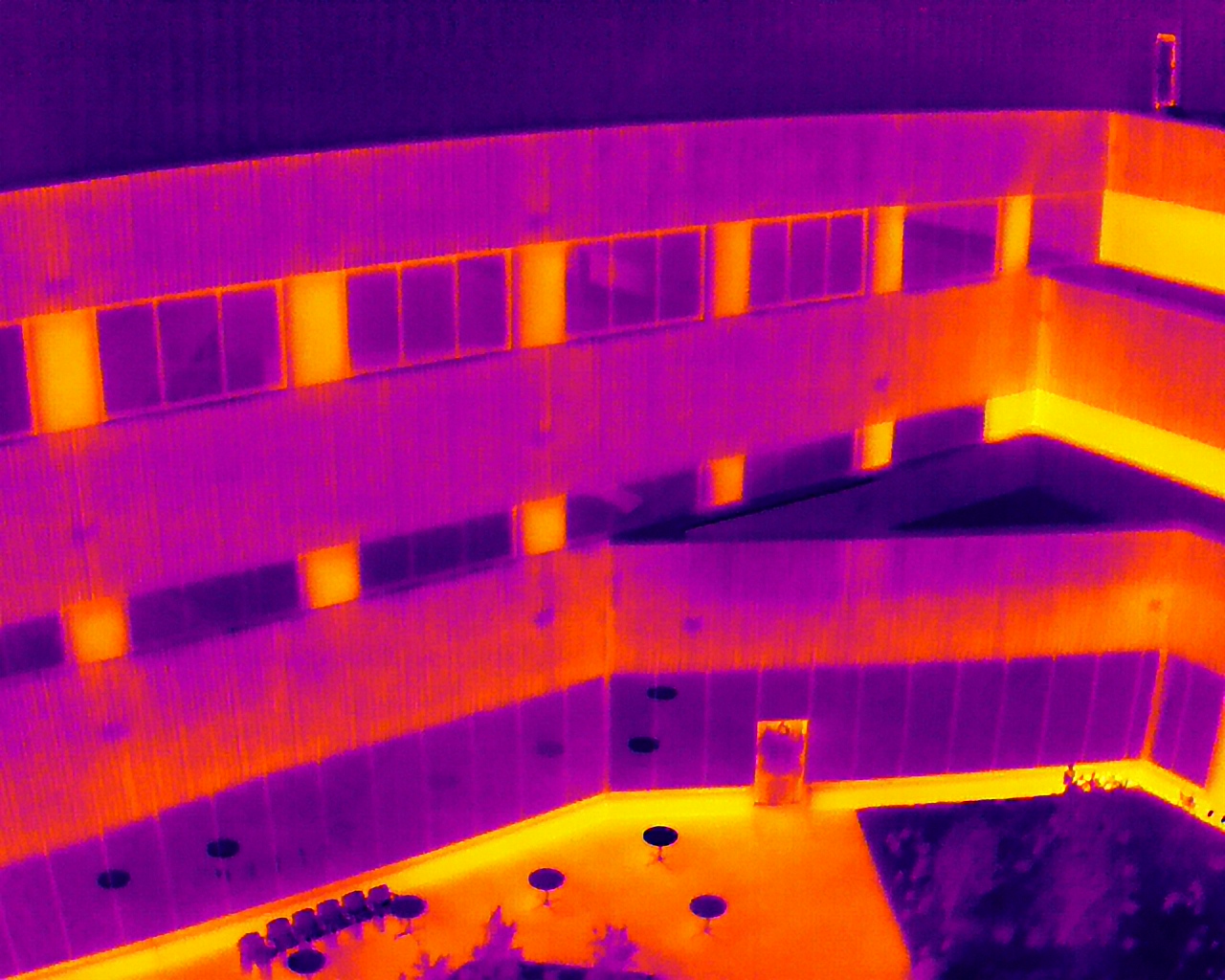

Today’s buildings demand higher performance standards than ever before. Traditional enclosure design methods, primarily focused on watertightness, are now insufficient to meet rigorous energy codes, heightened owner expectations, and the increasing complexity of enclosure systems.

Local regulations and climate considerations also significantly impact building enclosure design decisions. For example, coastal regions in California face additional pressures from marine environments, high UV exposure, and stringent local regulations such as Title 24 and the California Green Building Standards Code (CALGreen). Enclosures in Chicago, on the other hand, must adhere to the Chicago Construction Codes and the Chicago Energy Transformation Code to contend with cold, wet winters that require stricter attention to thermal performance and moisture control. Enclosures in Massachusetts—in a rapidly changing wet, cold, and coastal environment—need to meet stretch energy codes. Add in industry goals such as AIA 2030, SE 2050, and Passive House, and the pressure on building enclosures to perform at elite levels is high.

Failing to adapt to these changing performance expectations can lead to operational inefficiencies, increased maintenance costs, reduced occupant comfort, premature enclosure failures, and greater litigation risks associated with moisture intrusion and energy performance issues. Building enclosure commissioning (BECx) is a common and increasingly required approach to help project teams address these issues.

What Is BECx?

BECx is a structured quality assurance process to verify that the building enclosure—including walls, windows, roofs, and below-grade spaces—is designed, installed, and performs according to applicable codes and project-specific objectives. BECx comprehensively addresses key building enclosure considerations, such as the four barriers of the enclosure and their durability, reliability, redundancy, suitability, compatibility, constructability, and continuity.

A typical BECx quality assurance process includes:

- Reviewing Owner’s Project Requirements (OPR)

- Reviewing the Basis of Design (BOD)

- Peer reviewing design and construction documents

- Confirming that submittals and shop drawings conform to the established OPR and construction documents

- Conducting construction-phase site observations

- Observing and documenting the enclosure performance testing (air/water infiltration, thermal continuity) performed by a third-party testing agency

- Providing maintenance recommendations

Why BECx Has Evolved

BECx historically branched off from HVAC commissioning and has been refined over the years to apply to building enclosures. Its development has been guided by energy codes and industry guidelines such as ASHRAE, NIBS, and LEED. However, it has transformed into a critical risk management strategy for building owners and project teams.

Key factors driving this evolution include:

- Code changes: Building and energy codes are introducing stricter requirements for enclosure performance.

- Design complexity: Increasing complexity in detailing across enclosure systems, including facade, roofing, below-grade waterproofing, weather-resistive barriers, and rainscreen assemblies.

- Performance requirements: Higher owner expectations for durability, sustainability, and reduced lifecycle costs.

- Sustainability concerns: Expanded environmental, social, and governance reporting requiring demonstrable building performance.

BECx is no longer just a compliance measure but a critical strategy for managing enclosure complexity, regulatory compliance, and long-term risks.

Strategic Benefits of BECx

A BECx approach can help give the project team significant advantages:

- Enhanced energy efficiency: Minimizes energy losses through verified enclosure performance, which is crucial in environments with high solar exposure, extreme temperatures, or seasonal variability.

- Moisture and air leakage control: Proactively identifies and resolves potential issues, which is essential in a wide range of climates—from cold and dry to hot and humid.

- Material durability: Validates material selection and installation quality, reducing risks of degradation due to UV exposure, freeze-thaw cycles, thermal movement, and moisture.

- Risk mitigation: Reduces costly rework, project delays, and disputes by detecting design and construction issues early.

- Compliance assurance: Ensures adherence to evolving local and state performance standards, mitigating compliance risks.

Additional Considerations for Project Teams

A successful BECx process depends on thoughtful coordination across stakeholders. Owners and project teams should consider the following:

- Collaboration: BECx is collaborative. The commissioning provider will work with—not against—the design team to support the project vision while adding an independent layer of technical review. When the design doesn’t fully align with OPR, BECx helps identify gaps and guide the team toward compliance.

- Mockups and testing: BECx often includes pre-construction mockup testing for critical details and transitions. These early tests help reduce field requests for information, streamline installation, and avoid costly rework.

- Warranty and turnover support: A well-documented BECx process helps owners validate warranty requirements and supports a smoother turnover with robust as-built documentation and maintenance guidance.

- Cost vs. value: While BECx is an upfront investment, the long-term savings from improved durability, fewer callbacks, and reduced operational risk typically outweigh the initial cost, especially on large or complex projects.

- Independence and efficiency: While the Building Enclosure Commissioning Provider (BECxP) should be independent, frameworks like LEED allow the same firm to perform both consulting and commissioning if internal separation is maintained. Many owners prefer this model due to increased efficiency, fewer coordination issues, and faster resolution of recommendations. It is important that consulting and commissioning teams operate independently and only coordinate after key deliverables (e.g., peer reviews) are finalized, ensuring objectivity and streamlined communication. For some projects, however, a second firm may be preferred to provide a fresh perspective or added oversight.

When to Implement BECx?

BECx is recommended or mandated for:

- Projects pursuing high-performance certifications (e.g., LEED)

- Buildings subject to stringent energy regulations (e.g., Title 24 or stretch energy codes)

- Complex facade systems requiring precise oversight

- Projects in harsh climates or coastal locations

- Facilities with low tolerance for enclosure failures (e.g., labs, hospitals, museums)

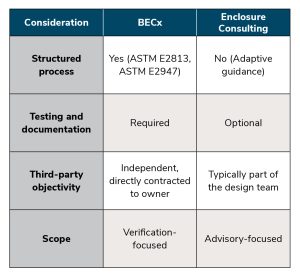

BECx vs. Building Enclosure Consulting

It’s important to distinguish between these services:

- BECx is a structured, third-party verification process that follows guides such as ASTM E2947 and standards like ASTM E2813, providing formal validation and oversight.

- Enclosure consulting offers broader advice on design, material selection, and troubleshooting without necessarily involving formal, sequential oversight or testing.

Conclusion

BECx is no longer just a compliance measure but a critical strategy for managing enclosure complexity, regulatory compliance, and long-term risks. Project teams, especially in challenging regions, benefit significantly from integrating BECx early into their projects.

To help ensure optimal building performance and project outcomes, it can be critical to start the BECx process early with an experienced BECxP and enclosure consultant who is well-versed in design approaches and local requirements.