Las Vegas, NV

Autodesk University 2016, Main Pavilion

Scope/Solutions

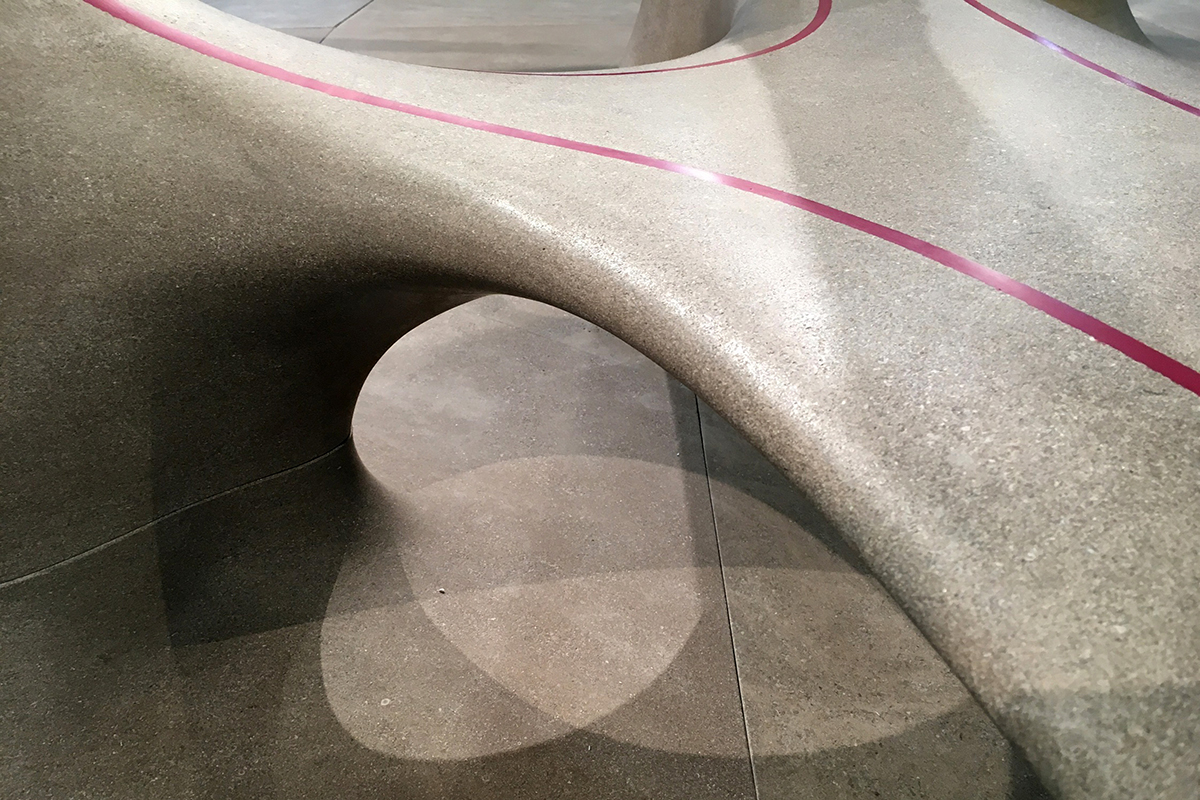

Autodesk University brings the design industry together each year for an exciting conference focusing on new ways to create. As the host, Autodesk is inspired to feature innovative design and construction in their own pavilion. Their 2016 Generative Design Pavilion included a custom-formed bench and integrated canopy. SGH provided technologically creative structural design and material testing services to help the design team accomplish the interesting exhibit.

The pavilion’s base and pillars are robotically carved from a single block of limestone and support a lightweight fabric canopy. At only 2 in. thick, the limestone bench required creative engineering to span 12 ft, while supporting its own weight and people. SGH developed a customized reinforcing approach, allowing the limestone to maintain its slender profile. Highlights of our work include the following:

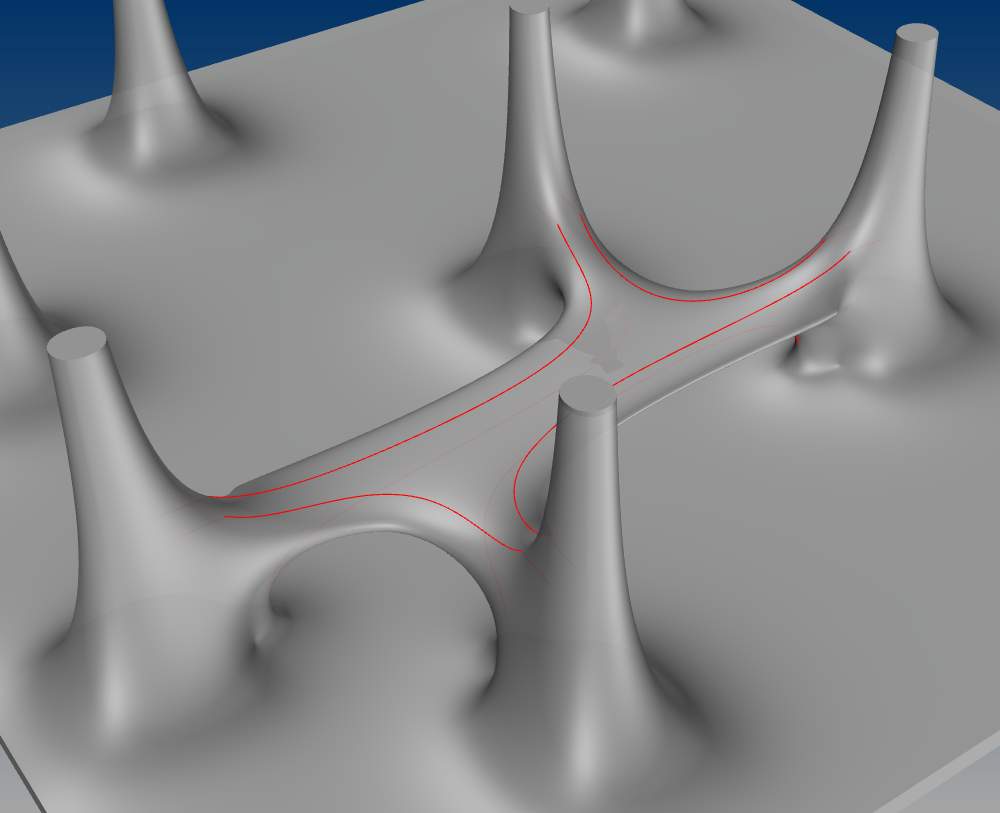

- Created structural forms for the bench and coordinated with the architect throughout the design process via three-dimensional Rhino models

- Developed a plan to reinforce the limestone with glass fiber rods embedded in epoxy, combining one of the oldest structural materials with one of the newest to accomplish the innovative structure

- Prepared finite element models to evaluate the bench structure and design reinforcement for the stone with a geometric profile to complement the benches’ geometry

- Tested limestone samples with glass-fiber rod reinforcement in our materials laboratory with a variety of epoxies and groove geometries

- Provided the final design information in a Rhino model, which was also used for fabrication and allowed the project to be completed entirely from digital information with no paper drawings or records transferred between the architect, SGH, or the fabricator

Project Summary

Key team members