Waltham, MA

Three-dimensionally Printed Glass Testing

Scope/Solutions

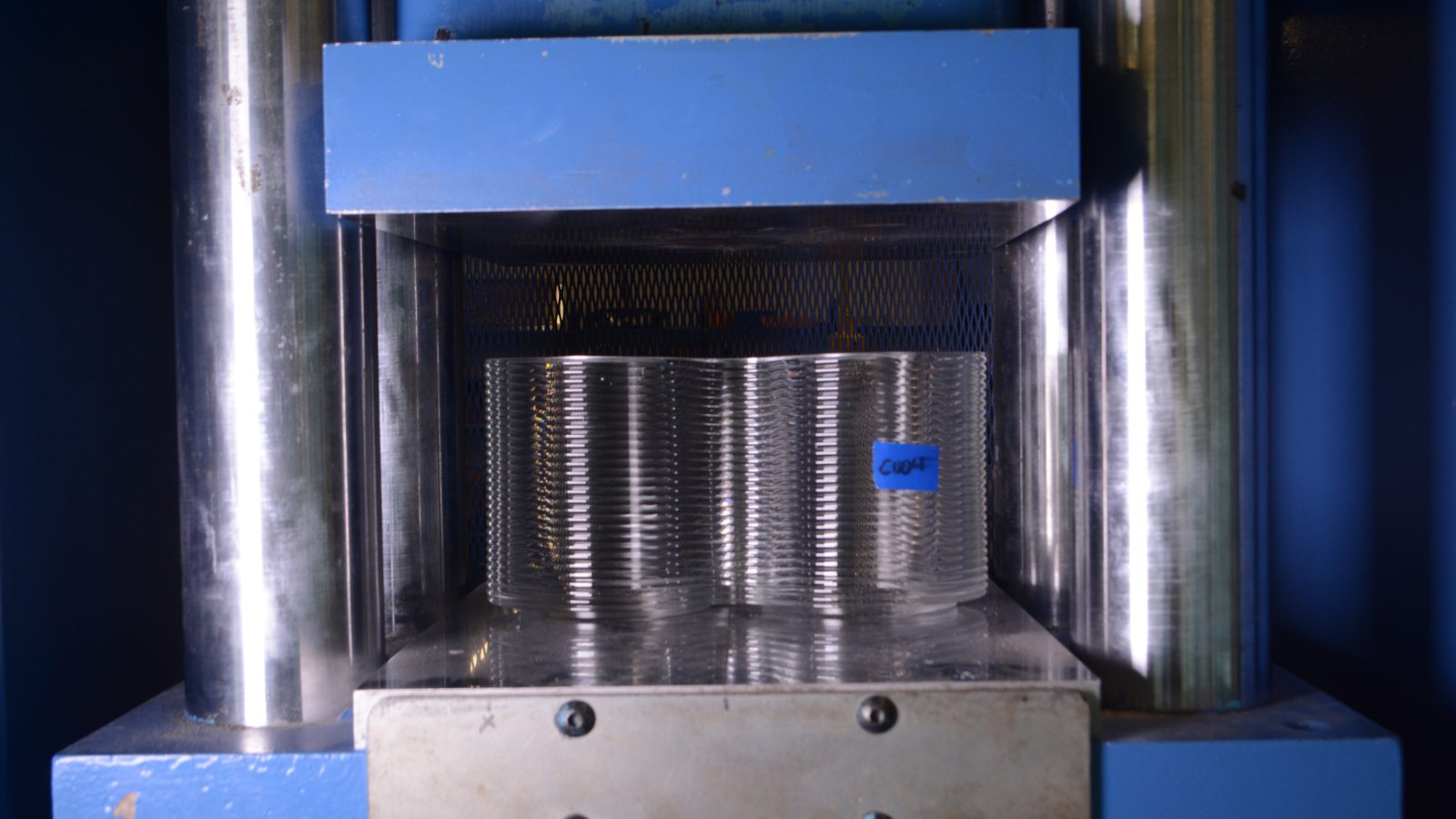

In 2017, SGH collaborated with the MIT Media Lab on an exhibit for Milan Design Week. The exhibit, Glass II, showcased intricately curved columns created with three-dimensionally (3D) printed silicate glass. We helped the team by designing post-tensioning support for the columns and performing physical testing in our Applied Science & Research Center. Looking to advance their research with a new geometry, MIT retained SGH to perform additional testing on 3D-printed glass samples in 2024.

SGH tested nineteen samples to determine the compressive strength of the assembly. Highlights of our work include:

- Conducting tests on a single glass unit with flat-plate boundaries and on a stacked assembly

- Testing with wooden and/or aluminum mounts to simulate use-case loading conditions

- Using a hydraulic testing machine with a 600 kip capacity

- Targeting a load rate of 1 kip/sec and manually controlling the rate of compression to compensate for deformations as the glass pressed into the mounts

- Monitoring the load and displacement throughout the testing using data acquisition software

Project Summary

Solutions

Evaluation

Services

Applied Science & Research

Markets

Education

Client(s)

Massachusetts Institute of Technology

Specialized Capabilities

Materials Science

Key team members

Additional Projects

Northeast

Massachusetts Institute of Technology, The Chapel (Building W15)

SGH consulted on the building enclosure and was the structural engineer for the project.

Northeast

Harvard Kennedy School Roof Replacement

The Harvard Kennedy School (HKS) campus consists of six interconnected academic buildings of varying height and age located around a central raised courtyard. SGH served as the designer of record for a multi-year, phased roof replacement project.