Waltham, MA

Sleeve Block Testing

Scope/Solutions

The unitized curtain wall units for a new high-rise building are fabricated with first anchors and sleeve blocks that attach the curtain wall to anchorage plates cast into the building structure. During construction, nail gun fasteners penetrated the sleeve blocks. The curtain wall fabricator required the contractor to test their capacity with the penetrations. SGH performed the testing to help the contractor determine whether or not the punctured sleeve blocks were structurally adequate.

SGH performed physical testing on samples of the aluminum sleeve blocks and fist anchors. We tested samples with and without penetrations so the project team could compare their capacity. Highlights of our work include:

- Reviewing the testing procedures required by the curtain wall fabricator

- Developing a test plan that met the requirements and was compatible with our laboratory, equipment, and instrumentation

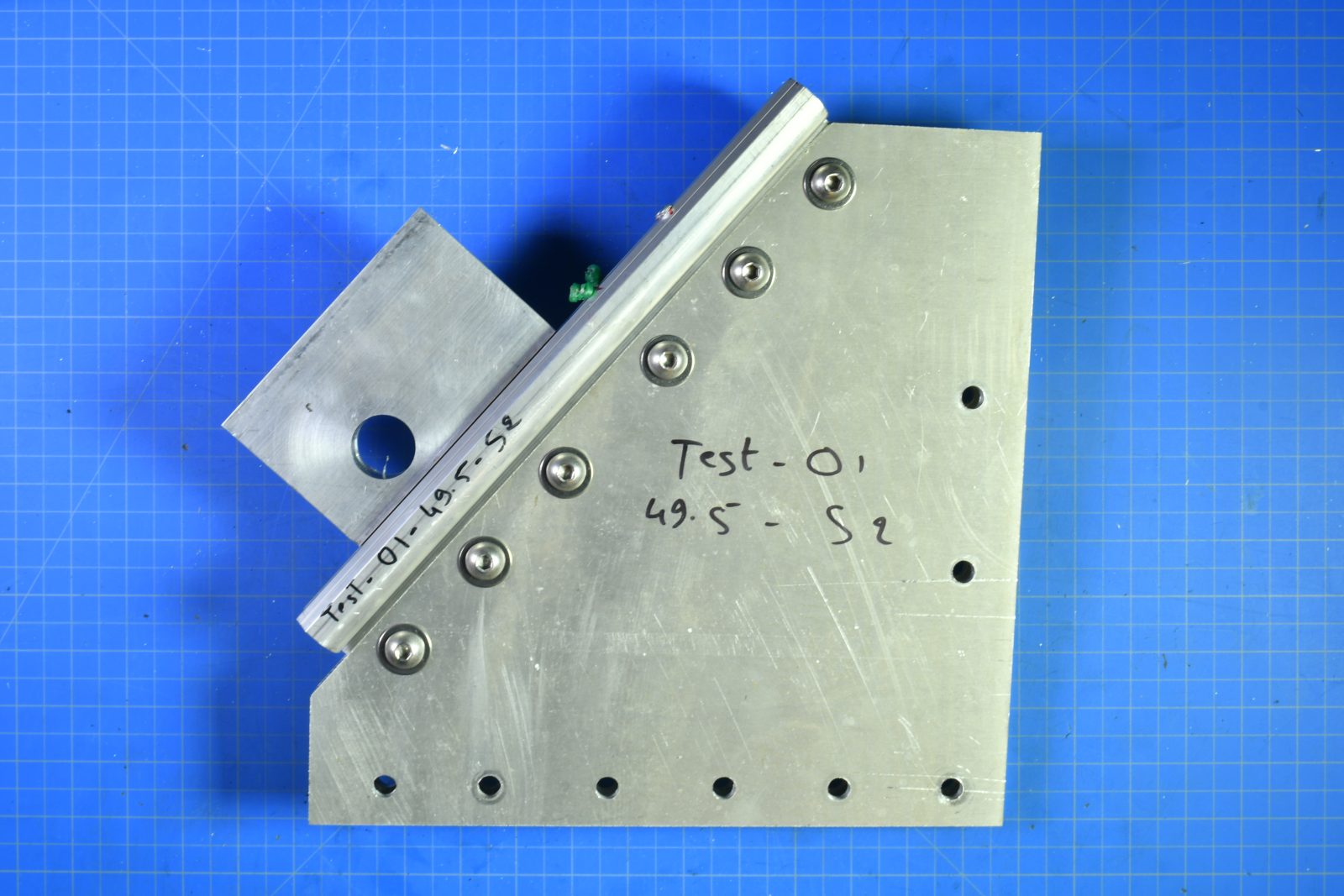

- Designing and machining a testing apparatus to hold the anchor and sleeve blocks in place at a specified angle to mimic the resultant force between the vertical design load and horizontal wind load

- Performing tensile load testing with our universal test machine

- Providing the project team with force and deflection measurements to compare the performance of samples with and without penetrations

Project Summary

Solutions

Repair & Rehabilitation

Services

Building Enclosures | Applied Science & Research

Markets

Commercial

Specialized Capabilities

Facades & Glazing | Physical Testing

Key team members

Additional Projects

Northeast

Paramus Park Mall

Corrugated metal storm drain pipes running beneath the Paramus Mall parking lot were severely corroded and deflected. SGH investigated the pipes’ condition and developed rehabilitation options that would help minimize disruption to the mall.

Northeast

53 State Street Roof Deck

Exchange Place at 53 State Street includes the 1896 Boston Stock Exchange and the modern glass-clad tower. SGH evaluated the existing structure to support the new roof deck and designed the structural supports for several new roof deck features.