Morenci, AZ

Precast Concrete Arch

Scope/Solutions

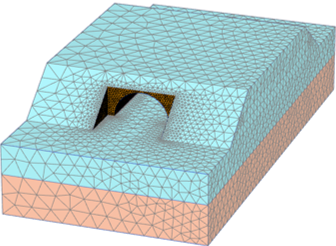

A precast concrete arch allowed mine vehicles to pass over U.S. Highway 191. A few months after the buried bridge was put into service, the mine operator observed separation of the headwall panels and longitudinal cracks in the highway, indicating differential settlement between the two footings. They retained SGH to investigate the bridge’s condition.

SGH used construction documents and field measurements to develop finite element models and evaluate the structural capacity of the bridge. Highlights of this work include:

- Creating two- and three-dimensional models of the arch to analyze soil-structure interaction and the effects of the differential settlement on the structure

- Calibrating our results to the field measurements of the settlement and change in span resulting from the footing movement

- Evaluating the capacity of the arch, considering the settled condition

Our analysis helped demonstrate that bridge still had sufficient capacity despite the settlement and could remain in service.

Project Summary

Solutions

Failure Investigation

Services

Structures | Advanced Analysis

Markets

Infrastructure & Transportation

Client(s)

Freeport-McMoRan

Specialized Capabilities

Repair & Strengthening | Marine & Civil Works | Buried Infrastructure | Computational Mechanics | Failure Analysis

Key team members

Jesse Beaver

Executive Principal, Engineering Mechanics and Infrastructure

Additional Projects

South

Port of Corpus Christi, Dock Fender Optimization Study

SGH conducted a study to review the existing infrastructure and provide recommendations for improving the fender systems at eleven oil docks, three solid bulk handling docks, and seven general cargo docks.

South

White Rock North, Water Transmission Main Failure Investigation

The White Rock North Water Transmission Main is a prestressed concrete cylinder pipeline, embedded cylinder type, which delivers 200 million gallons a day of treated water. SGH was hired as a subconsultant to perform a failure investigation of the transmission main after a pipe segment ruptured.