Allston, MA

Harvard University Science Complex, MWRA Sewer

Scope/Solutions

Harvard University planned to locate a new science complex above a Massachusetts Water Resources Authority (MWRA) brick masonry pipeline that was over 115 years old. The University was concerned about the impact of construction on the 69 in. high by 62 in. wide active masonry sewer. SGH studied the potential effects of ground displacement that can distort and increase soil loads on buried structures, construction traffic live loads, surface vibrations, and impacts from falling objects.

Highlights of SGH’s work to assess pipeline response to construction-induced vibration and movement include the following:

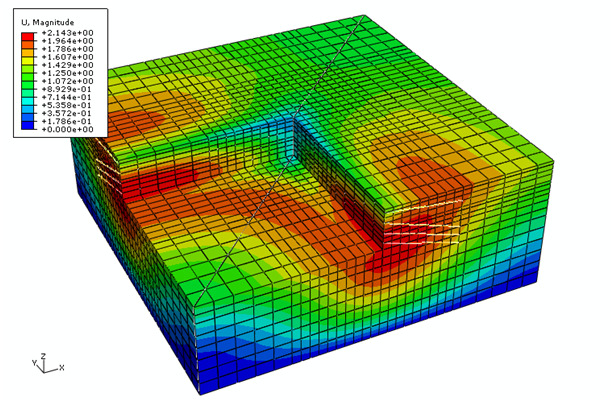

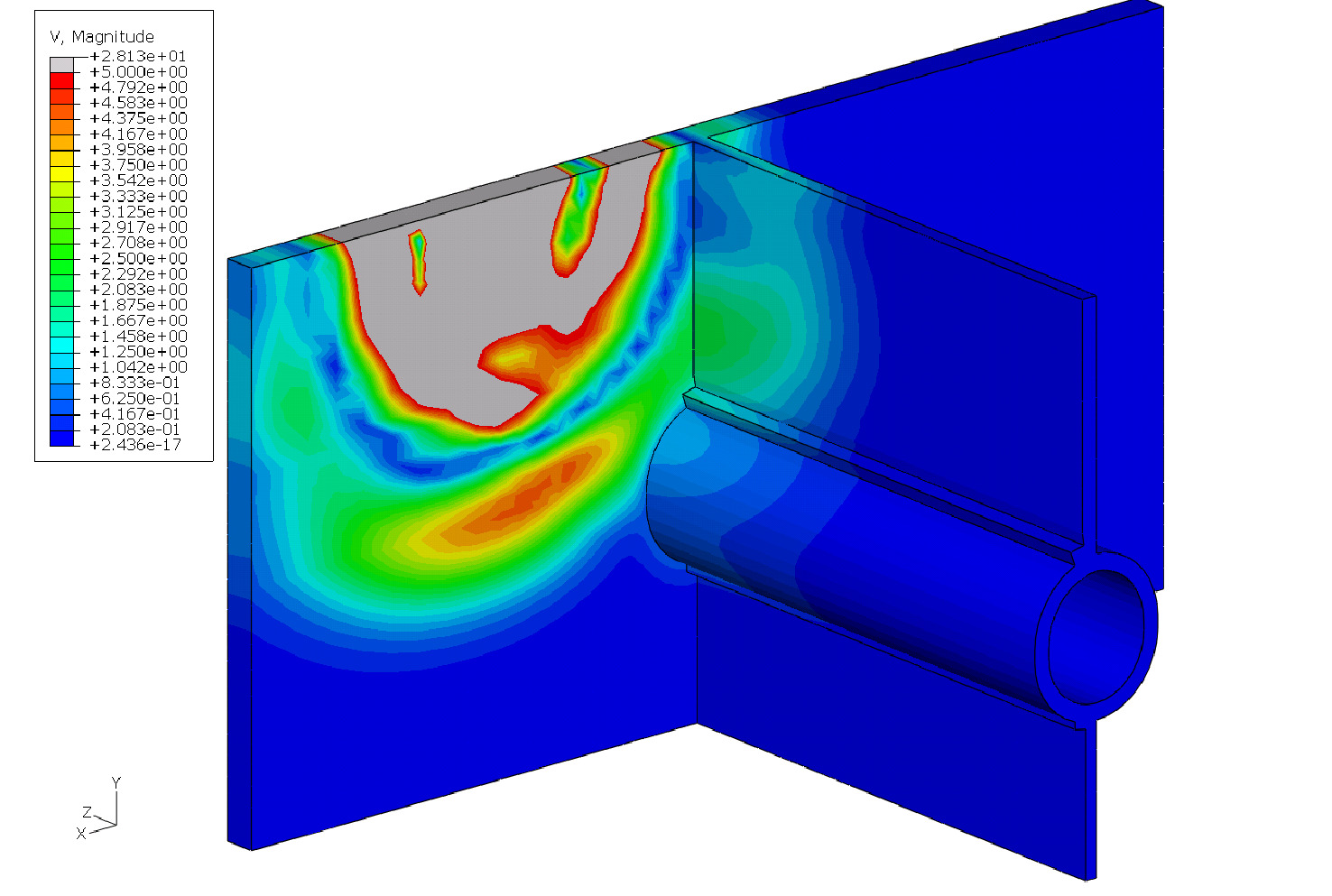

- Examined the sequences of both Boston blue clay excavation and installation and tensioning of a tie-back system

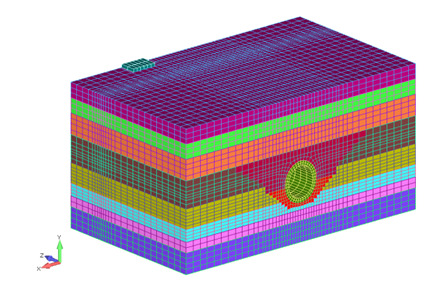

- Used ABACUS Explicit to develop three-dimensional soil-structure interaction models

- Analyzed stress-wave propagation through the soil

- Assessed the extent of ground displacement

- Modeled construction of the slurry wall adjacent to the pipe using nonlinear finite-element soil-structure interaction analysis

- Used different nonlinear soil models, such as Mohr-Coulomb in ABAQUS, to simulate the soil layers, buried and above-grade structures, and construction processes

- Collaborated with the owner, contractor, and other consultants, enabling Harvard to proceed with the project without endangering the pipeline

To minimize impact, the design of the four-building research complex wraps around the pipeline.

Project Summary

Solutions

Repair & Rehabilitation

Services

Advanced Analysis

Markets

Infrastructure & Transportation

Client(s)

Sea Consultants, Inc.

Specialized Capabilities

Buried Infrastructure | Computational Mechanics

Key team members

Additional Projects

Northeast

MBTA Kendall/MIT Station Entrance

As part of the Kendall Square Initiative—a collaborative development created by the Massachusetts Institute of Technology (MIT) and private partners—the MBTA Kendall/MIT station was upgraded with a new headhouse designed to improve accessibility.

Northeast

Logan International Airport Terminal E

After the contractor placed the 4 in. thick overlay, they observed lifted slab edges, cracks, and hollow-sounding areas in some locations. The contractor retained SGH to investigate the problem and provide repair options.