Washington, DC

Crash Performance for Lightweight, High Speed Trains

Scope/Solutions

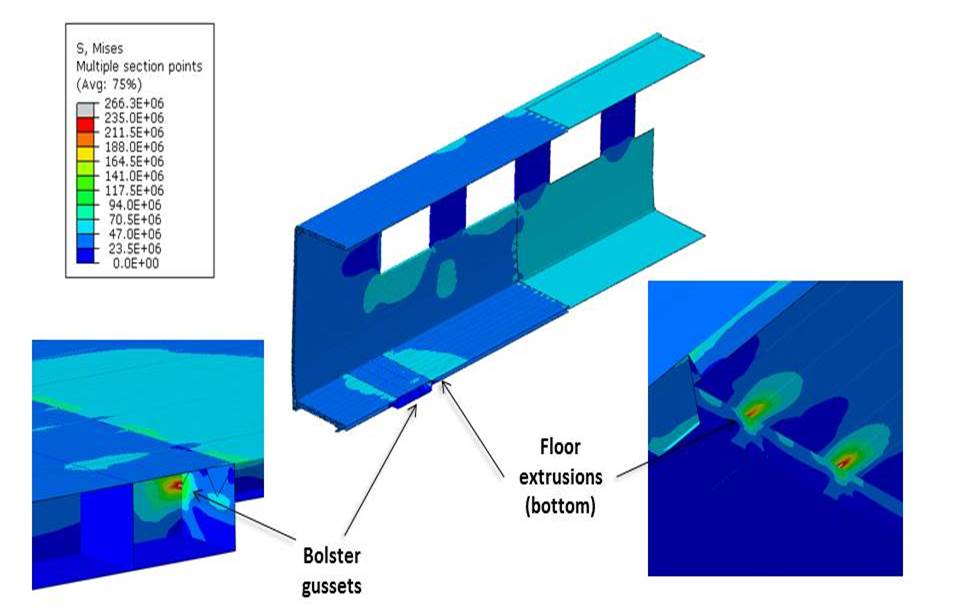

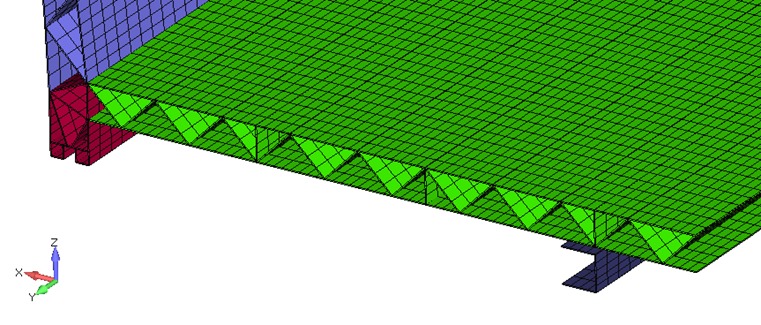

The high speed train industry relies on relatively lightweight equipment to conserve energy and to minimize the effects on infrastructure and rolling stock design. Recent crashworthiness recommendations presented by the Federal Railroad Administration (FRA) Engineering Task Force (ETF) to improve collision safety could lead to increased train weight and the high speed train industry requested further evaluation. Working for the FRA, SGH evaluated existing technology and the resulting impact on the weight of the train.

For this project, SGH identified the existing systems listed below and assessed the effects of the higher level of performance on weight.

- Occupied volume structure

- Energy absorption systems and components

- Coupler technologies, including pushback couplers

- Anti-climbing systems

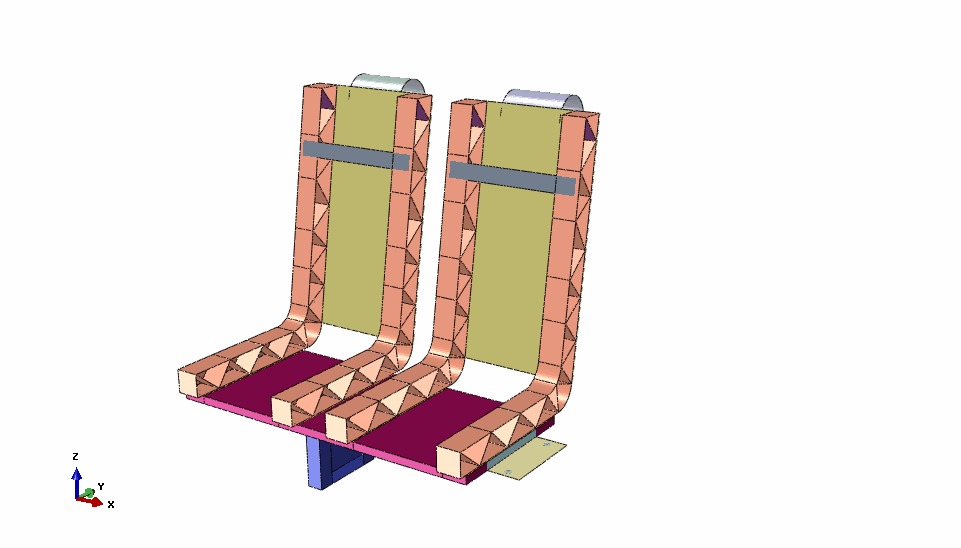

- Interior components, including seats

- Fire protection systems

SGH’s work on this project also included the following tasks:

- Investigation of current lightweight train component technology in Europe and Asia

- Investigation of lightweight technologies in other industries, including the aircraft industry

- Finite element analysis to establish a relationship between crash performance and weight for vehicle strength, seat strength, and structural fire resistance

Project Summary

Solutions

New Construction

Services

Advanced Analysis

Markets

Infrastructure & Transportation

Client(s)

Federal Railroad Administration

Specialized Capabilities

Computational Mechanics

Additional Projects

Mid-Atlantic

William Preston Lane Memorial Bridge

Constructed in 1973, the westbound structures of the William Lane Memorial Bridge carry three lanes of U.S. Route 50 across the Chesapeake Bay. Working with O’Connell & O’Connell, SGH investigated the cause of debonding and helped develop of repair procedures for the 5 mi. long structure.

Mid-Atlantic

Back River Wastewater Treatment Plant, Egg-Shaped Digesters

Crom Corporation designed and built two 3.0 MG egg-shaped sludge digesters for Baltimore's Back River Wastewater Treatment Plant. SGH performed a peer review of the structural design of the new digesters.