Tuscon, AZ

Central Arizona Project

Scope/Solutions

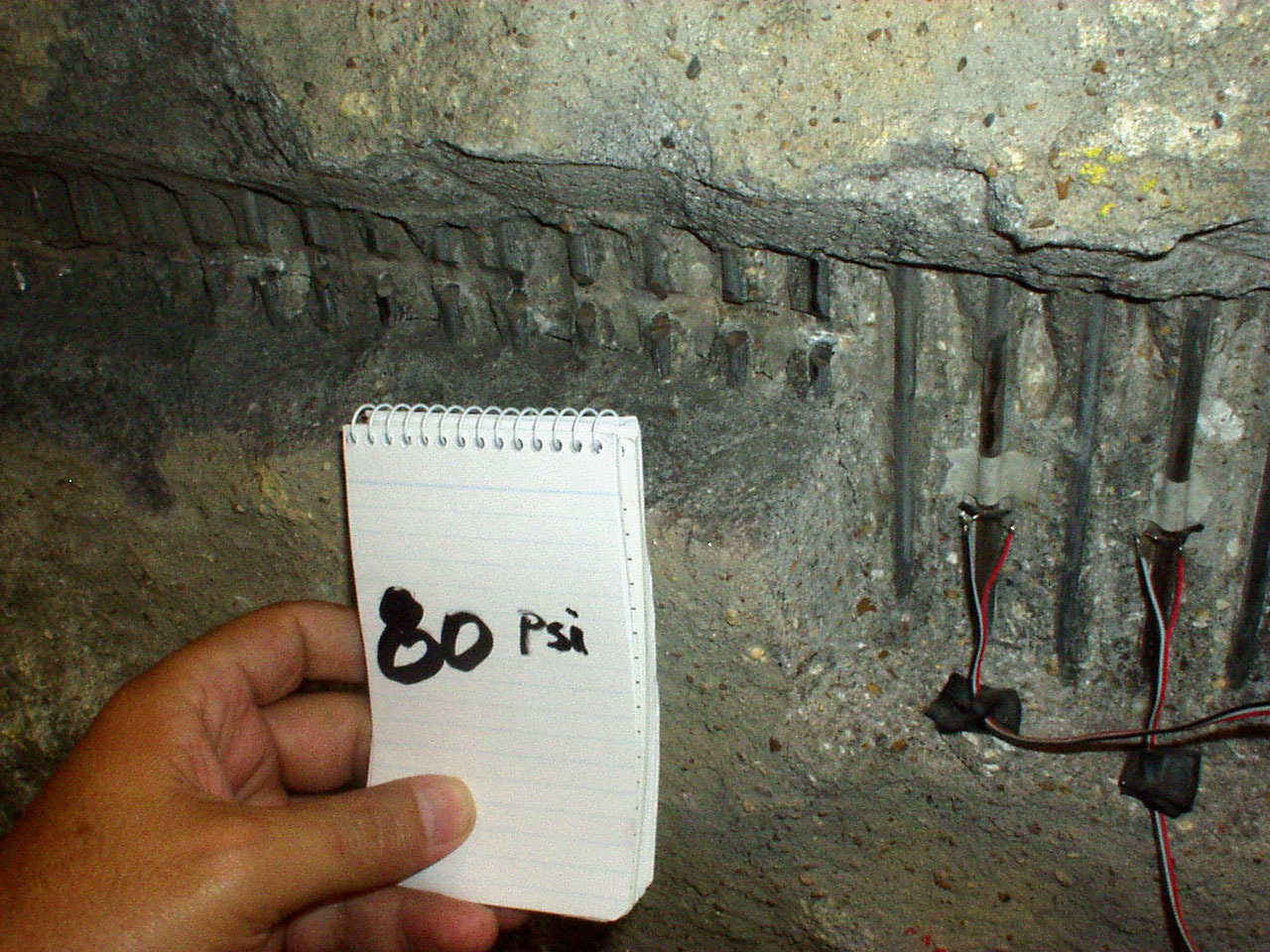

The 252 in. dia. concrete pipe is used in siphons to convey water in the Central Arizona Project and is the largest diameter pipe in the world. The pipes have a 19.625 in. thick concrete core and two prestressing wire wraps. Using electromagnetic testing techniques, several noncylinder prestressed concrete water conveyance pipes were identified to have broken prestressing wires. SGH evaluated the failure risk resulting from the loss of prestress, determined pipe repair priorities, and subsequently designed post-tensioning repairs and safe excavation for the repair pipe.

Highlights of SGH’s work include the following:

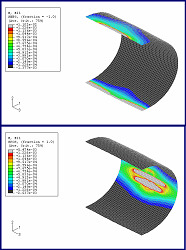

- Computed the earth load and the load distribution on the pipe using a finite element soil-structure interaction program

- Computed the combined effects on structural safety of internal pressure, dead loads, prestress, and prestress loss as wires break in an area

- Determined the failure risk for the pipe and prioritized repairs for the distressed pipe based on its failure margin and its proximity to cracking, structural damage, and rupture

- Developed a post-tensioning repair design for pipe under 15 ft of soil cover and up to 75 ft of water head

- Computed the maximum safe excavation length under the pipe with broken wires assuming that the pipeline is either empty or full of water

Project Summary

Solutions

Failure Investigation | Repair & Rehabilitation

Services

Advanced Analysis

Markets

Infrastructure & Transportation

Client(s)

Central Arizona Project

Specialized Capabilities

Buried Infrastructure | Risk & Resilience Assessment

Key team members

Additional Projects

West

New Marine Terminal

SGH prepared conceptual designs and developed design criteria for replacement of the entire marine terminal.

West

Indian Valley Reservoir

The Indian Valley Reservoir provides long-term irrigation storage and flood control. A 2010 inspection report recommended seismic analyses of the floodgates and control structure to confirm the gates could be raised following a earthquake. SGH evaluated the seismic performance of the two structures.