Topic Brief

Ten Things You Need to Know About Flooring Failures

November 12, 2014

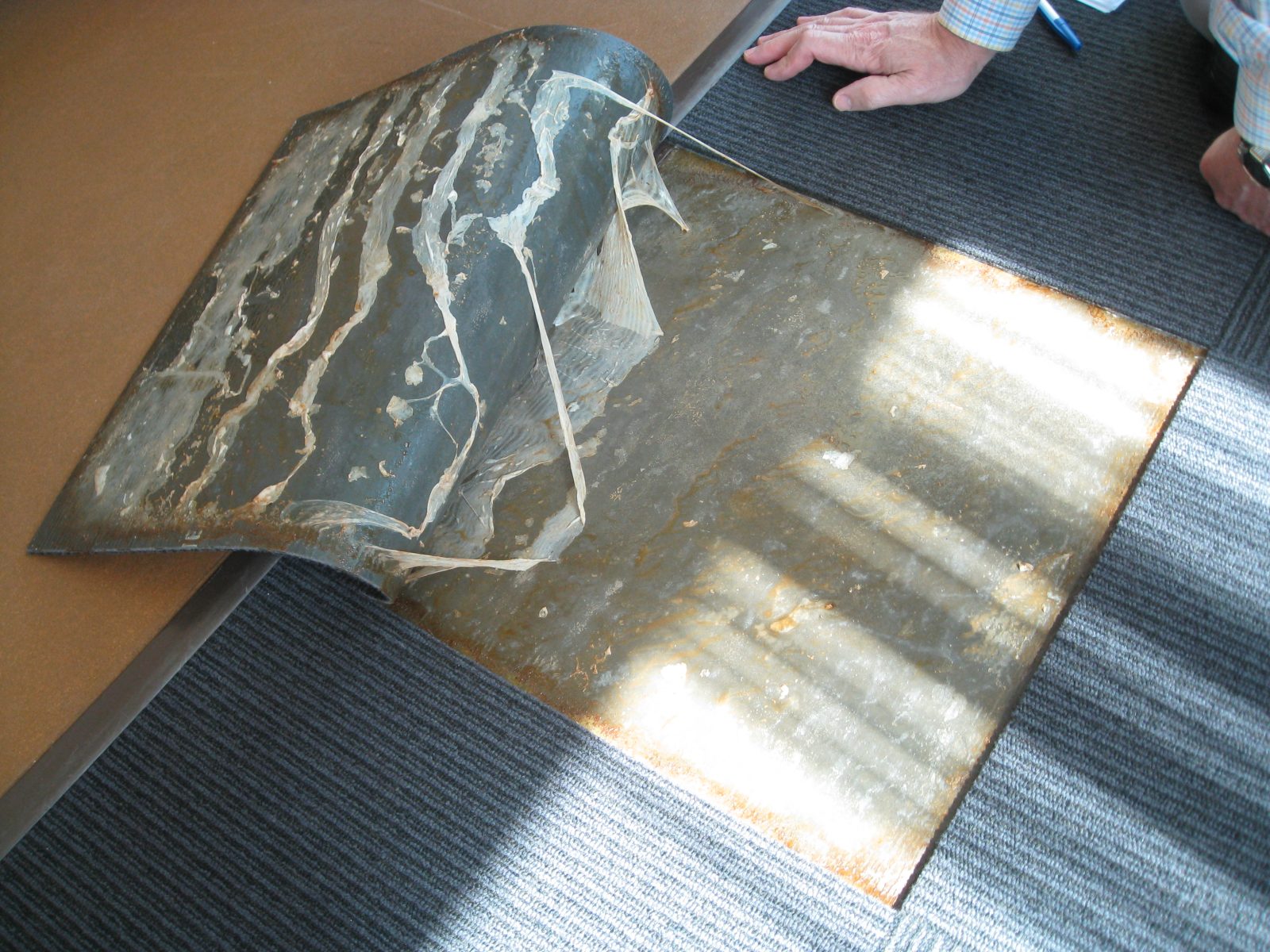

Moisture-related floor finish failures on concrete slabs have become more prevalent due to changes in concrete mix design, fast-track construction, and regulation of volatile chemicals. Moisture-induced deterioration of floor finishes can result in delamination, discoloration, blisters, re-emulsification of adhesives, mold growth, and odor generation. These failures can be costly, delay occupation, or require operational disruption for repairs.

Blistered epoxy floor coating

However, several approaches can improve the performance of concrete floor finishes, such as the following:

- Limit the initial water content. Water is an integral component of concrete for cement hydration and workability, but excess water can lead to flooring failures. Concrete mix designs with a lower water/cementitious material (w/cm) ratio contain less water and take less time to dry.

- Reduce fly ash content. Concrete with fly ash and other supplemental cementitious materials (SCM) can be strong and durable and may also qualify for LEED credits for recycled content. However, these concretes are typically denser than concrete made only with portland cement and this reduction in density also reduces the porosity of the concrete, which can significantly increase drying time.

- Avoid curing compounds. Film-forming, liquid curing compounds retain water in the concrete until proper hydration occurs, but curing compounds limit concrete drying until their removal. Temporary covers provide proper hydration without adversely affecting drying time.

- Use a vapor retarder. Concrete slabs-on-grade are permeable and allow moisture from underlying soils to permeate and contact moisture-sensitive finishes. Installing an effective vapor retarder below the slab protects floor finishes from moisture that originates in the soil.

- Eliminate blotter layers. The intent of a blotter layer (i.e., a sand layer between the vapor retarder and concrete slab) is to reduce the tendency of the slab to curl as it dries. However, moisture trapped in the blotter layer during construction adds to the total moisture load stored in the floor, which will later diffuse through the concrete and contact moisture‑sensitive finishes.

Design and construction of a building is a complicated process, and many factors can contribute to high concrete-slab moisture levels.

Moisture testing at floor slab

- Conduct proper moisture testing. Regardless of the design, it is imperative to test concrete slab moisture levels prior to flooring installation. The results can vary greatly depending on construction procedures and a certified tester should assess the slabs once the building is enclosed and at operational temperature and humidity.

- Select moisture mitigation systems cautiously. When moisture levels exceed flooring manufacturers’ limits, a topical moisture-mitigation coating may be useful. However, some moisture mitigation systems are ineffective and have contributed to flooring failures. Select an appropriate moisture-mitigation system by considering its moisture vapor permeability, performance track record, and compatibility with other floor-system components.

- Consider the moisture sensitivity of the floor finishes. Some floor finishes are more moisture tolerant than others. Upgrading to more moisture tolerant adhesives or selecting finishes with greater permeability could be successful on moderately wet slabs.

- Plan ahead. Conversations about flooring installation typically do not occur until the end of a project. At that point, changes to design and installation procedures can increase costs and compromise completion times. Discuss ways to reduce the risk of floor finish failures during the design and pre-construction phases to increase the chance of a successful installation.

- Specify moisture-mitigation measures. Design and construction of a building is a complicated process, and many factors can contribute to high concrete-slab moisture levels. Assume that, despite the project team’s good intentions, moisture levels may be high. Specify a moisture-mitigation plan in the base bid. By including test procedures and an appropriate moisture-mitigation system, you can minimize change orders and schedule delays.