Researching Carbon Sequestration in CLT Composite Bolted-Steel Buildings

Can hybrid steel-cross-laminated timber (CLT) structures be carbon-negative?

To answer this question, Simpson Gumpertz & Heger is working as a core member of a research team led by Northeastern University Professor Jerome F. Hajjar. The research project, “HESTIA Project 4C2B: Century-Scale Carbon-Sequestration in Cross-Laminated Timber Composite Bolted-Steel Buildings,” is funded through the U.S. Department of Energy’s Advanced Research Projects Agency-Energy (ARPA-E) program.

Our team aims to guide the design of multi-story carbon-negative prototype buildings that would revolutionize how the construction industry tackles the climate crisis. I am working alongside SGH’s Director of Applied Science & Research Norman Perkins, who is serving as project principal for our work to provide both structural and fire services.

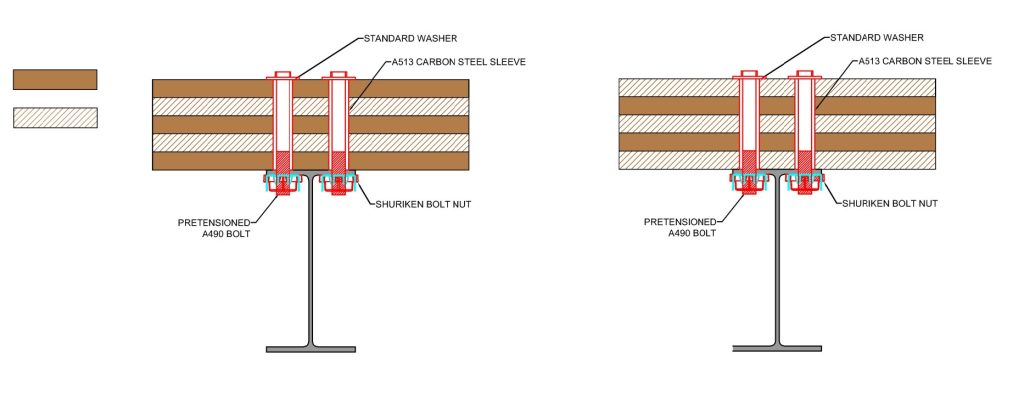

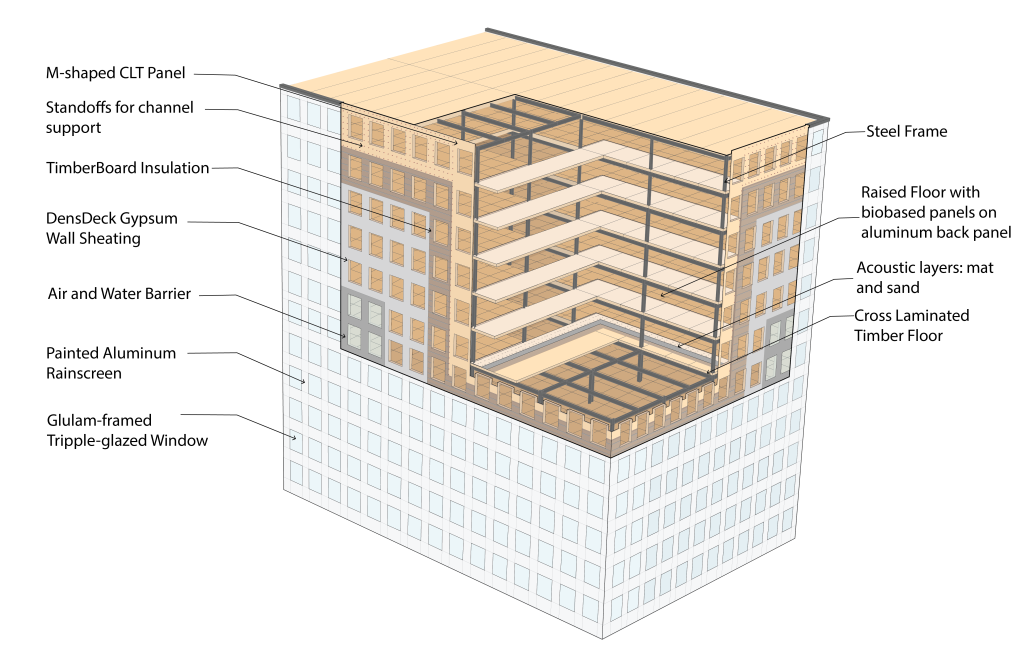

There is a lot of untapped potential within the construction industry when it comes to reducing a building’s carbon footprint. Most steel-framed buildings constructed today use composite concrete-on-steel-deck floor systems that are not readily deconstructable at end-of-life. We are designing a composite CLT floor system supported by steel framing that uses less structural steel and can be deconstructed after the building’s use. CLT floors can store up to 50% of their weight in biogenic carbon, so offer a more sustainable option than typical concrete-on-steel-deck floors. The team is designing deconstructable composite connections between the steel beams and CLT floors that will have the strength and stiffness to force the steel and wood to act together compositely, allowing for smaller beams. Additionally, the deconstructable design will allow the components to be disassembled at the end of a building’s life so they can be reused in new buildings. Both of these strategies will reduce the carbon emissions associated with the system, with the goal of net carbon negativity.

Our physical test specimens are based on the prototype building designs. The team at Northeastern will be testing to failure full-scale composite beam assemblies in its Burlington, MA, structures lab. The research team also plans to conduct diaphragm tests. When the testing is complete, SGH will use the test and analysis results to lead the development of design recommendations that will allow practitioners to design these systems. The team is also evaluating the fire and acoustical performance of the proposed system. Through our efforts, we will be laying the groundwork for possible future code changes to facilitate wide use of this more climate-friendly approach to building. A carbon-negative future is possible, and I am grateful to be part of this team working to get us there.

The three-year project began in 2022 and will be complete in 2025. In addition to myself and Norm, the SGH team includes Megan Ladd, Danielle Paille, Chase Slavin, Anindya Dutta, Michael Richard, Qianru Guo, Madison Di Vico, Xia Yan, and Scott Tomlinson.