Passive House Design for High-Performance Building Enclosures

The building enclosure is at the core of Passive House (PH) design—it is the “passive” system that regulates energy transfer. The mechanical and other “active” systems supplement the enclosure design to maintain the desired interior environment. Understanding how these passive and active systems interact and affect one another is crucial to achieving PH certification.

By coordinating modeling, design, and construction strategies—and integrating building systems—PH projects can greatly reduce energy consumption and improve occupant comfort while adding resiliency and flexibility for owners.

Passive House Design Principles

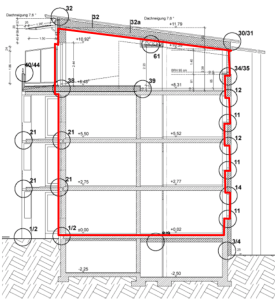

Delineating the thermal barrier and identifying all potential thermal bridges is the first step to improving energy performance.

PH practitioners focus on the following to inform design:

- Compactness: use a low ratio of envelope surface area to interior volume.

- Solar control: use orientation, space planning, and enclosure design to minimize solar gains.

- Insulation: provide as much insulation as possible to reduce thermal transmission.

- Windows: use windows with very low U-factors to minimize energy loss through what is typically the weakest point of the thermal enclosure.

- Airtightness: limit conditioned air leakage and reduce potential for condensation and drafts.

- Thermal bridges: avoid heat loss through thermal bridges, which can be exacerbated in highly insulated buildings.

- Ventilation: use systems with heat and energy recovery and verify that they will meet PH energy targets.

Passive House Benefits

The ultimate goal of PH design is to reduce energy consumption and improve occupant comfort, be it for high-rise buildings or single-family homes. Enhanced performance leads to several ancillary benefits for the design team.

Most PH designs include high-performing windows, skylights, and doors because they have a substantial impact on reducing mechanical system loads. Lower loads lead to smaller mechanical equipment that consumes less energy, operates more efficiently, and occupies less space in the building. Smaller equipment, ducts, and pipes can offset the increased cost of a better-performing enclosure while also leading to greater design flexibility for architects and more rentable space for owners. Space planning can also be more creative with smaller mechanical room sizes and less rooftop equipment.

Another equally important goal is to improve thermal comfort. Continuous insulation and air barrier systems allow the interior surface temperature of the exterior enclosure systems to be much closer to the ambient air temperatures, thereby reducing thermal discomfort. Energy losses from air leakage can be reduced by designing continuous and effective air barrier systems, which also will reduce drafts and make occupants more comfortable.

Critical Capabilities

A successful PH project team should feature interdisciplinary expertise and utilize an integrated approach. Consideration of key building enclosure principles throughout the design and construction phases is critical.

In the design phase, a building enclosure consultant should:

- Integrate the construction team early in the design process to review the PH process and requirements.

- Assist with preparing an energy model to demonstrate compliance with PH standard.

- Perform thermal analysis to quantify losses through fenestration and thermal bridges as inputs for the energy model.

- Perform hygrothermal analysis to select appropriate membranes and insulation types to reduce condensation risk.

- Prepare detailed drawings and specifications that maintain air barrier continuity and reduce thermal bridging.

- Help select appropriate interior finish materials (e.g., low VOC, certified low-emission).

During construction, the enclosure consultant should:

- Actively participate in preconstruction meetings and assist with reviewing field mockups.

- Closely monitor building enclosure construction progress and educate construction trades on how their work impacts the overall success of a project.

- Perform or witness quantitative whole-building air leakage testing to verify air barrier performance criteria.

- Perform or witness qualitative testing (e.g., infrared, tracer smoke) of the air barrier to locate air leakage sites.

- Perform or witness mechanical duct air leakage testing and mechanical system commissioning.

The ultimate goal of PH design is to reduce energy consumption and improve occupant comfort, be it for high-rise buildings or single-family homes.

Conclusion

A coordinated project team and interdisciplinary approach is necessary to design and construct PH-certified buildings. Working together, teams can build high-performing buildings that offer greater flexibility and improved energy performance for enhanced comfort and resilience.