Fall River, MA

Brightman Street Bridge

Scope/Solutions

During the six-year rehabilitation of the Brightman Street Bridge, SGH provided investigation and concrete design services and performed testing, analysis, and thermal modeling of mass concrete placements.

SGH helped evaluate the following:

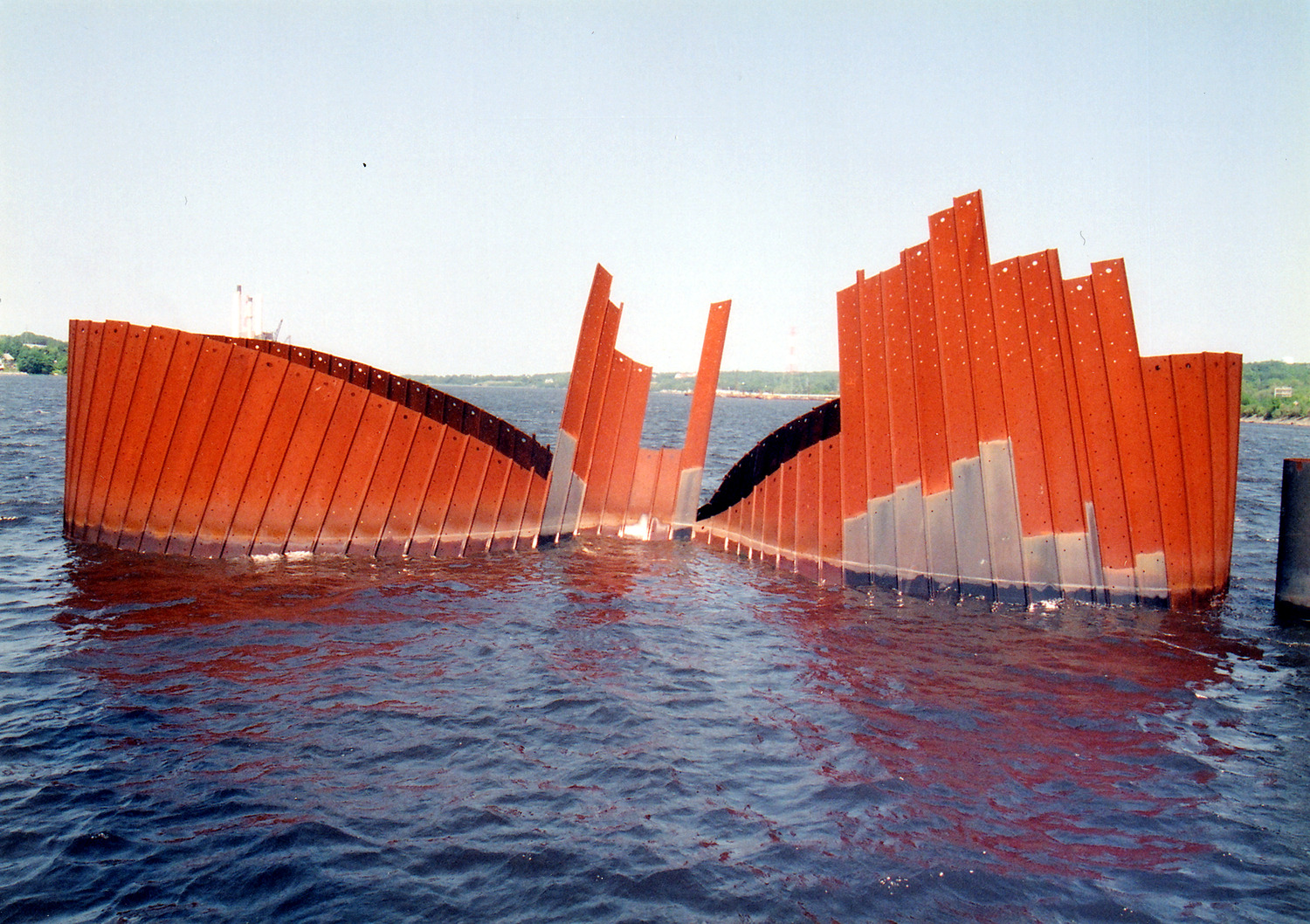

- Issues with tremie placement for an underwater cofferdam seal that compromised concrete quality

- Contractor concerns about a concrete mix for approach span pier pile caps and bascule span fender beams

- Plugged concrete pumplines during placement of the east bascule pier pile cap in cold weather

- Mass concrete placements

Over the course of these projects, SGH completed the following:

- Investigated tremie failure and blocked pumplines

- Determined the cause of the failed mass concrete placement in the cofferdam seal

- Performed petrographic analysis, adiabatic heat signature testing, and thermal simulations at varying placement temperatures, weather conditions, and curing periods

- Modeled heat generation during curing

- Retrieved and tested concrete core samples

- Designed and tested physical properties of a replacement tremie concrete mix and monitored a trial placement

- Proposed concrete aggregate and mixes to suit each project

- Specified tremie and mass concrete sequencing and placement methodology

- Recommended ways to avoid freezing pumplines, including increasing the concrete temperature, insulating pumplines, and filling the pumplines with hot water prior to pumping the concrete

- Monitored concrete placements for the 2002 and 2004 projects

Project Summary

Solutions

Repair & Rehabilitation

Services

Structures | Advanced Analysis | Applied Science & Research

Markets

Infrastructure & Transportation

Client(s)

Modern Continental Construction

Specialized Capabilities

Temporary Construction | Marine & Civil Works | Computational Mechanics | Physical Testing | Materials Science | Microscopy

Key team members

Additional Projects

Northeast

MTA Subway Station Elevator Replacements, New York, NY

Portions of the New York City subway have been open for more than 100 years and many stations do not meet modern accessibility standards. SGH consulted on fire life safety aspects of the installations.

Northeast

MBTA Kenmore Square Bus Station Canopy

The Kenmore Station Bus Canopy, designed by architect DiMella Shaffer, is part of the Kenmore Square Public Improvements Project. SGH performed a detailed review of the structural glass design and provided guidance on fabrication and constructability.