Miami, FL

Miami-Dade Government Center

Scope/Solutions

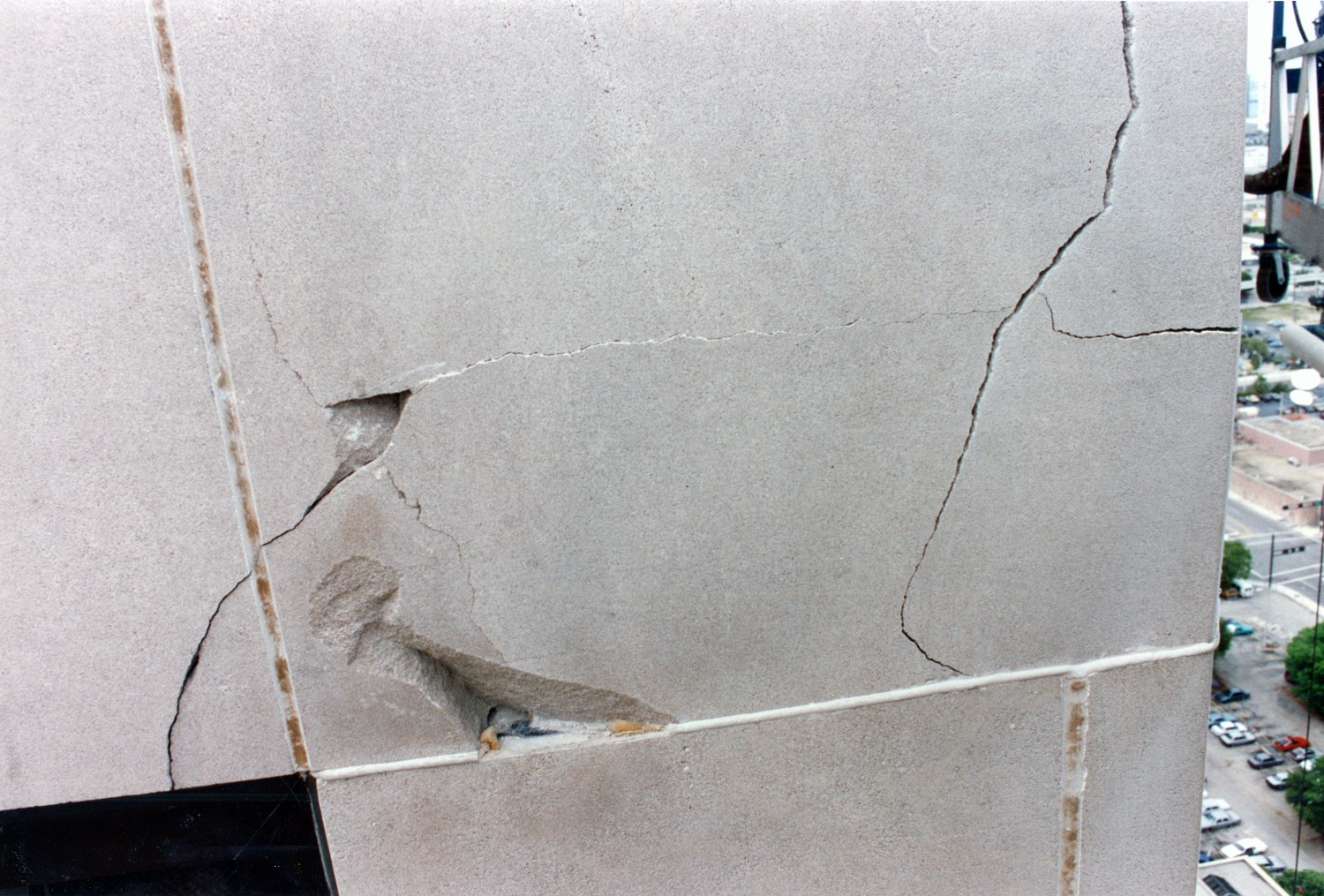

When pieces of the 4 in. thick limestone facade began falling off the 500 ft tall Miami-Dade Government Center, SGH investigated the cause of distress.

Highlights of our work include the following:

- Condition assessment of the limestone panels

- Use of vibrating wire strain gauges connected to a central data logger connected to our office in Massachusetts that allowed us to monitor movement between the limestone cladding and the backup structure to an accuracy of 1/10,000 in.

- Prediction of long-term panel movement to minimize remedial work and to verify the extent of thermal movement of the facade once the soft joints were installed

- Analysis of wind stress on panels using a relational database and finite element models

- Development of remedial contract documents for patching spalled panels, replacing panels with significant cracks, installing soft joints to isolate cladding from structure, and re-anchoring 7,500 panels

SGH found that the lack of soft material in the vertical joints between adjacent panels cause accumulation of lateral movement resulting in panel fractures and spalls at building corners. At the time of trial, our expert testimony resulted in a settlement that covered all repair costs.

Project Summary

Solutions

Repair & Rehabilitation

Services

Building Enclosures | Advanced Analysis | Structures | Applied Science & Research

Markets

Government

Client(s)

Miami-Dade County

Specialized Capabilities

Repair & Strengthening | Condition Assessments | Failure Analysis | Environmental Simulations

Additional Projects

Southeast

Spartanburg County Courthouse

Spartanburg County required a new courthouse to meet their current and future needs. SGH consulted on the building enclosure design and construction.

Southeast

Polk County Justice Center

Shortly after construction of the Polk County Justice Center, the building experienced several serious issues, including interior humidity levels that exceeded eighty percent, heavy roof and wall leakage, and brick veneer that cracked and bulged.