Monroe, MI

Fermi 2 Nuclear Power Plant, Circulating Water Pipeline

Scope/Solutions

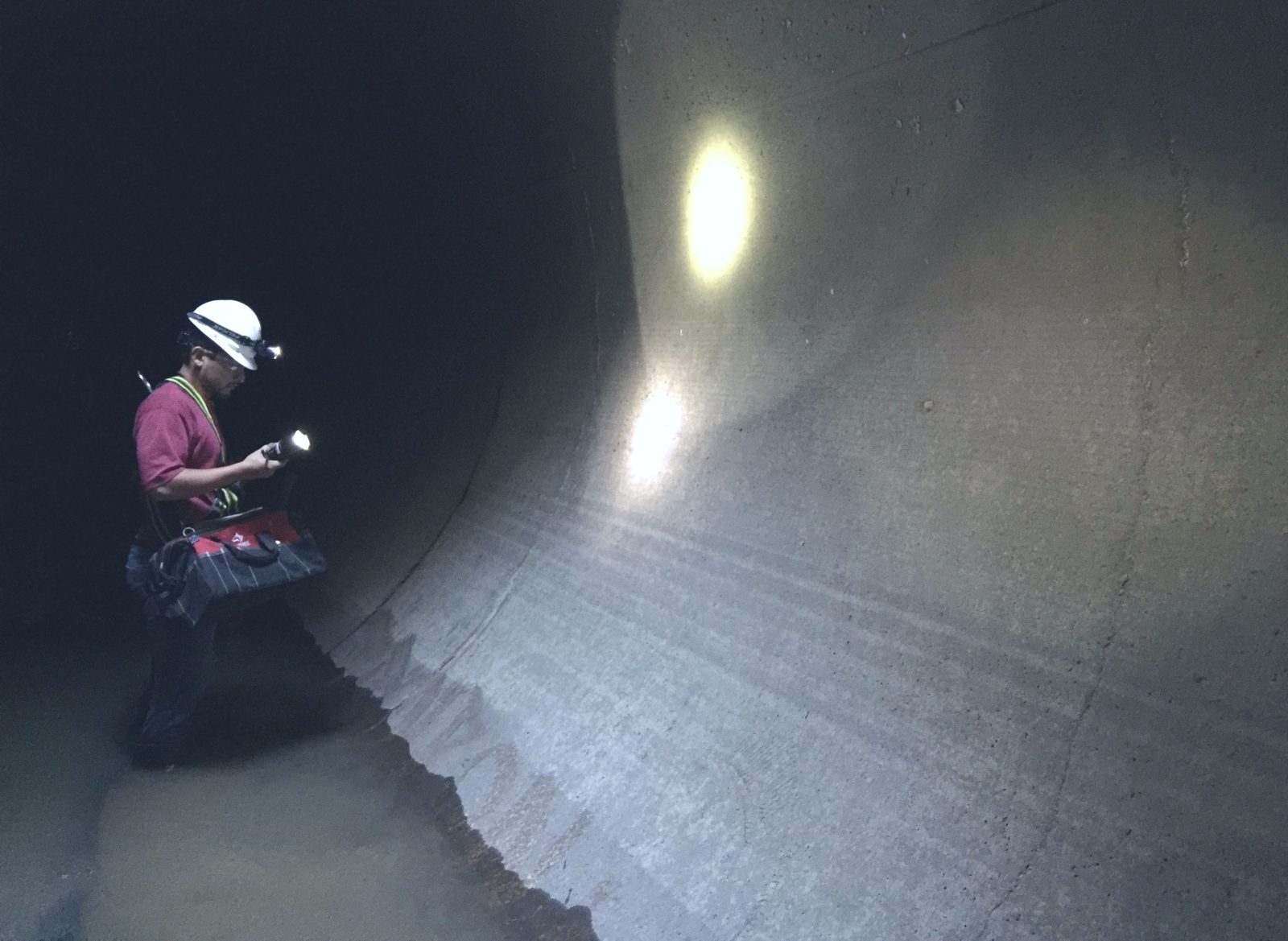

The 144 in. dia. circulating water pipeline at Fermi 2 consists of two intake lines between the reservoir and condenser and two discharge lines between the condenser and two cooling towers. All four pipelines are prestressed concrete cylinder pipe (PCCP) manufactured in the early 1970s. SGH first developed a design basis document and specifications for carbon fiber-reinforced polymer (CFRP) pipeline repairs, determined failure risk, and prioritized repairs for distressed pipes in the East and West Supply Lines. SGH then provided engineering support for repairs to the East Supply Line.

For the design basis document and specifications, SGH developed repair design criteria, inspection procedures, and repairs for the PCCP. Based on presumed distress, our documents serve as a guideline for DTE Energy to help them anticipate possible repairs, including CFRP pipeline repairs, repairs to joints with missing grout, repairs of leaking joints using inner seal, repairs to the damaged concrete inner core, and repairs to joints between PCCP pipes and adjacent steel piping.

SGH also performed visual and sounding inspections and failure risk analyses of the East and West Supply Lines. We determined the failure risk of the distressed pipes and prioritized pipe repairs. SGH designed all CFRP repairs and repairs to concrete cores. We provided continuous engineering support throughout construction, including quality assurance inspections and laboratory testing of CFRP properties and degree of cure.

Project Summary

Key team members