Boston, MA

Boston Harbor Islands

Scope/Solutions

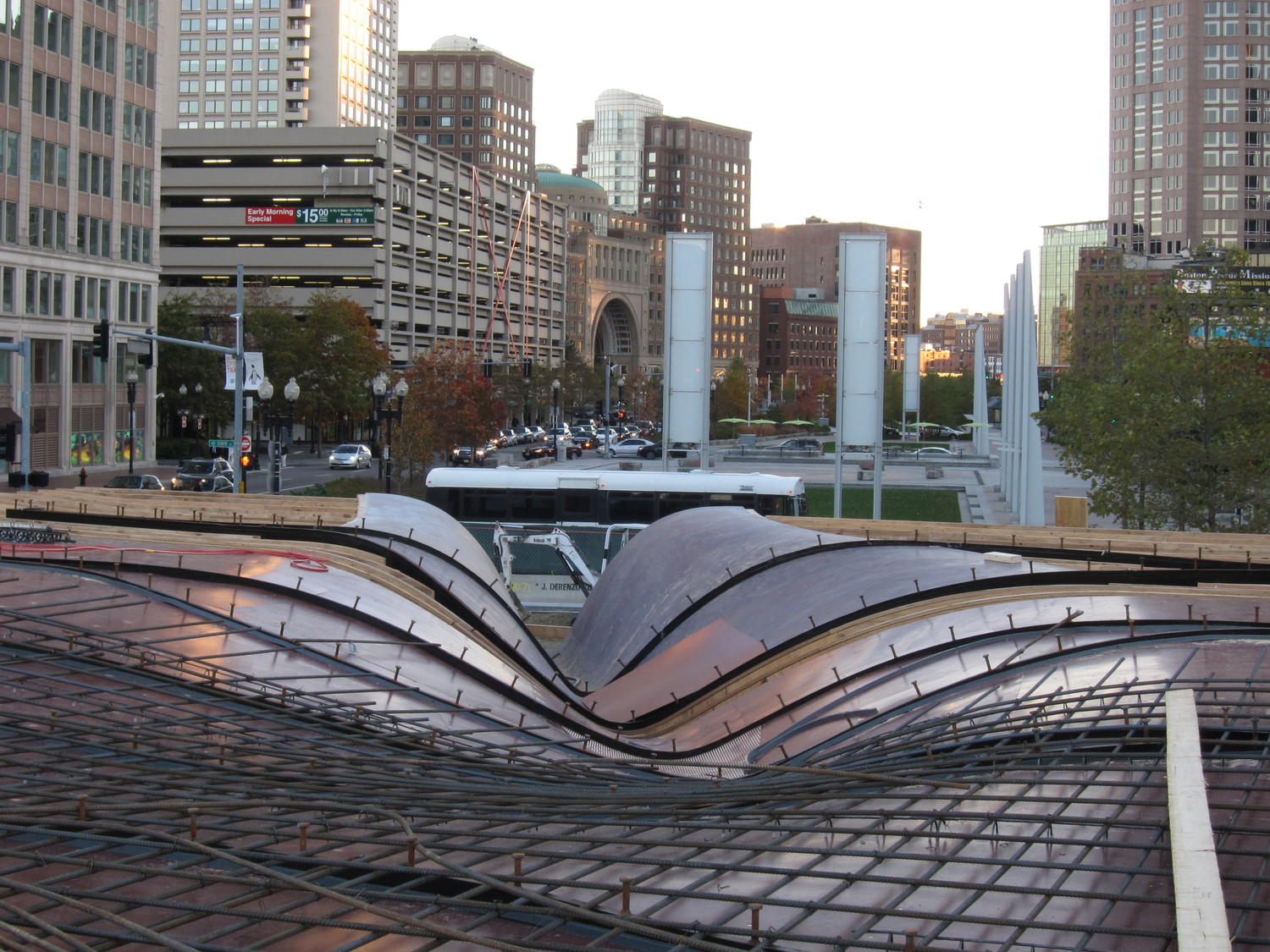

The Boston Harbor Island Alliance and the National Park Service wanted the first permanent structure on the Rose Kennedy Greenway to act as a beacon, attracting people to Boston’s Harbor Islands. In collaboration with Utile, SGH designed the structure; specified materials; and advised on all detailing, fabrication, and construction methods for the unusually-shaped roofs and the load-sensitive site.

SGH worked with the architect, contractor, formwork fabricators, and concrete subcontractors to coordinate design and construction.

We assisted the construction team by helping them develop and optimize their process for fabricating the complicated formwork. Highlights of our work include the following:

- Evaluated three-dimensional milled foam before recommending wood and wood-like materials for the formwork

- Developed exacting specifications that enabled the formwork fabricator to use computer numerically controlled (CNC) machinery for cutting and shaping the components

- Facilitated simultaneous fabrication of the curved wood and steel ribs to achieve tight integration of shop-fabricated, field-assembled, and cast-in-place elements

Our work also included the following structural and construction engineering services:

- Analyzed the supporting concrete and steel structure

- Configured transitions from columns to rebar in the concrete roof

- Observed mockups of the concrete surfaces

- Calculated acceptable construction loads for the site, which is only 4 ft above the Central Artery/Tunnel

- Developed a site diagram for the contractor identifying safe paths for heavy equipment

Project Summary

Key team members