Various Locations

Vertical Installation of Corrugated Steel Pipe

Scope/Solutions

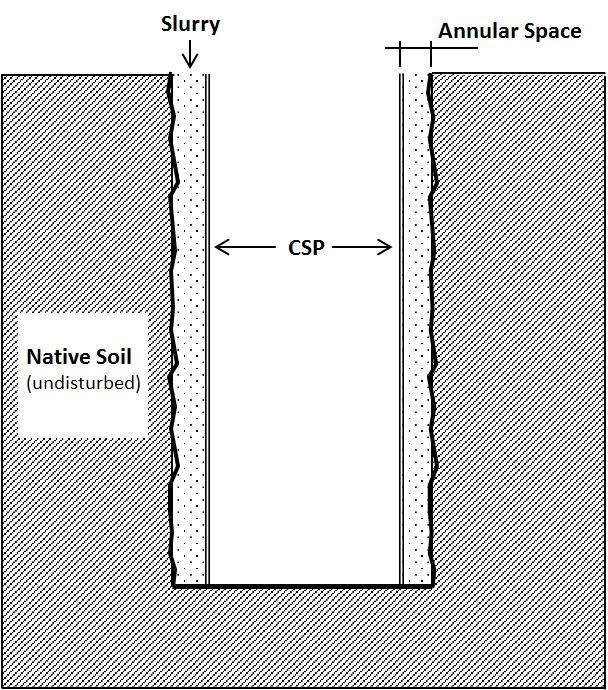

Contech Engineered Solutions (Contech) installs corrugated steel pipe (CSP) to form wind turbine foundations. After excavating, Contech installs the pipe vertically within the hole and quickly backfills around it with a concrete/slurry mix to prevent the excavation from caving in. At that stage – after the pipe is backfilled and before the interior is filled with concrete – the pipe must resist the lateral pressure from the slurry. SGH helped Contech by evaluating the pipe’s potential for buckling.

SGH reviewed the proposed installation plans and visited select sites to observe the construction process. We evaluated the pipe sections (up to 16 ft in diameter) to determine the capacity. We also studied how the width between the pipe and the unexcavated soil (annular space) and the slurry’s consistency/placement rate affect the pipe’s potential for buckling, considering the stiffening effects of the pipe’s corrugated wall.

Based on our analysis, SGH determined the variables associated with placing the slurry significantly affected the potential for buckling and proposed methods to calculate buckling loads for a specified height of slurry and to determine the corrugated pipe capacity need to resist the loads. We also recommended Contech increase the slurry’s slump and further study of the mix design to develop an optimal consistency.