Plymouth, MA

Pilgrim Nuclear Power Station Frac Tank

Scope/Solutions

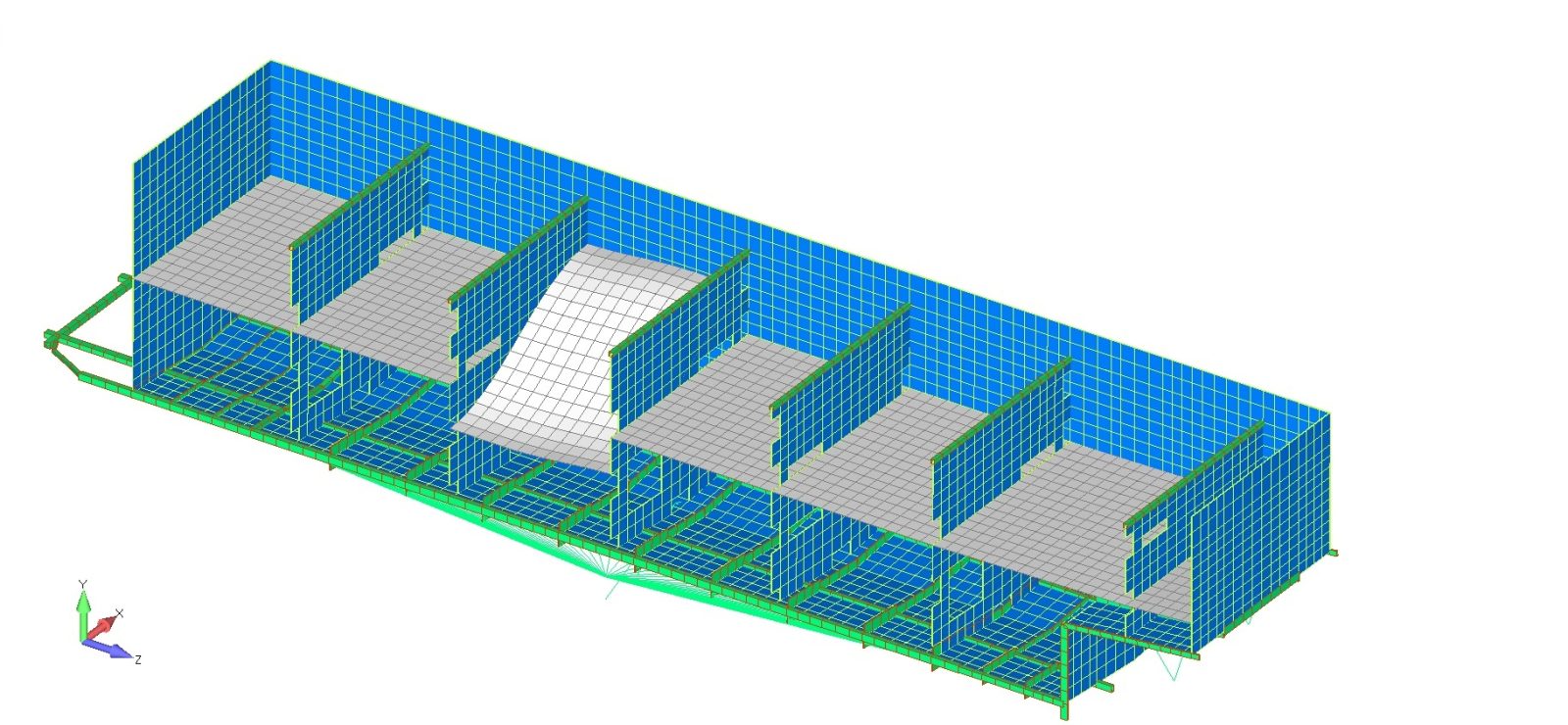

In response to Nuclear Regulatory Commission (NRC) post-Fukushima (FLEX) requirements, Entergy sought to install a 21,000 gal, mobile frac tank for temporary water storage at their Pilgrim Nuclear Power Station (PNPS). SGH evaluated the structural and seismic performance of the steel tank, manufactured by PCI Manufacturing, LLC.

SGH reviewed the design proposed by PCI Manufacturing, LLC and provided recommendations to ensure adequate strength and stability. Highlights of our work include the following:

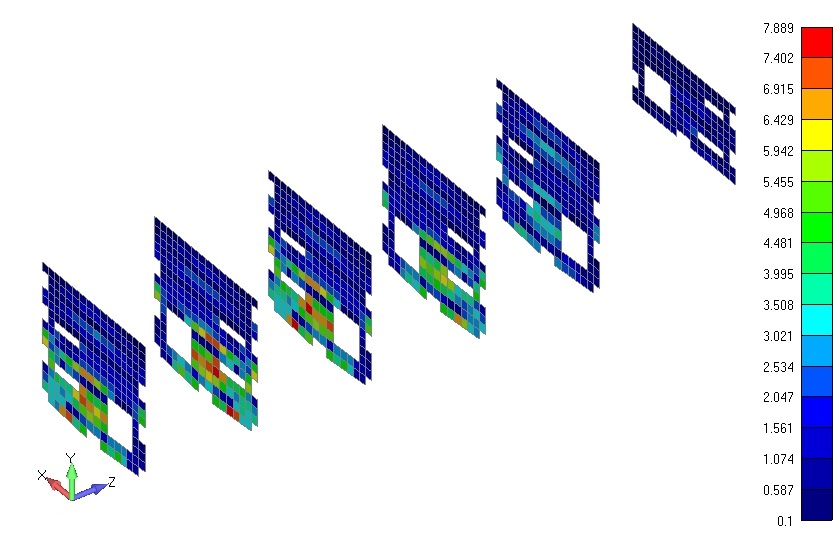

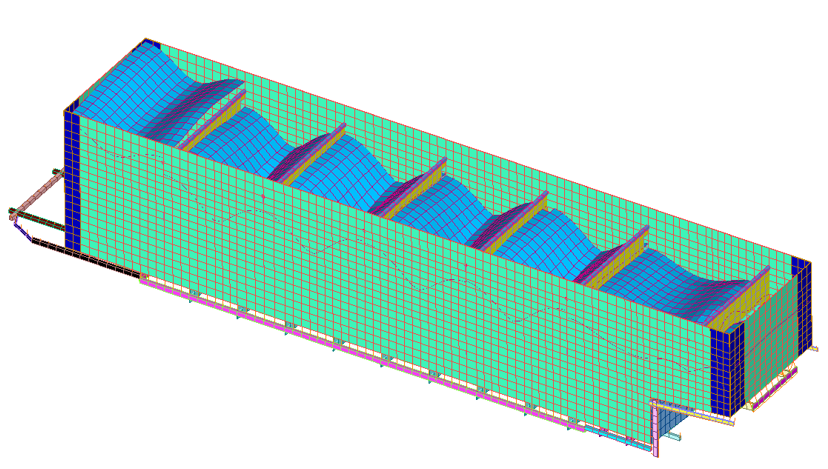

- Completed a response spectra fluid-structure interaction analysis of the frac tank for FLEX ground response spectra Safe Shutdown Earthquake (SSE) and Operating Basis Earthquake (OBE) cases, impulsive and convective (sloshing modes) for multiple fluid water levels, and sloshing effects on the tank roof per ANSI/AWWA A121

- Evaluated the structural adequacy of the tank to resist a combination of seismic and non-seismic demands

- Designed structural modifications to ensure all component stresses were below allowable values per ANSI/AISC N690 and 360

- Inspected the frac tank structure for conformance to the design requirements

- Analyzed proposed welds following ANSI/AISC provisions and inspected welds in final configuration per AWS D1.1

- Evaluated stability of the frac tank using nonlinear sliding and overturning provisions of ASCE/SEI 43

Project Summary

Solutions

New Construction

Services

Structures | Advanced Analysis

Markets

Science & Defense

Client(s)

PCI Manufacturing LLC

Specialized Capabilities

Seismic Engineering | Nuclear

Key team members

Additional Projects

Northeast

Portsmouth Navy Yard, Modular Submarine Enclosure

The contractor engaged SGH to assess the damage and design repairs to restore the damaged modules to their original condition.

Northeast

Massachusetts Institute of Technology, Haystack Radar Antenna Elevation Structure

Massachusetts Institute of Technology/Lincoln Laboratory initiated a major upgrade of the Haystack radar antenna requiring replacement of the elevation structure. The upgrade program was jointly sponsored by the United States Air Force and the Defense Advanced Research Projects Agency.