United States

Nuclear Station Low-Pressure Service Water System

Scope/Solutions

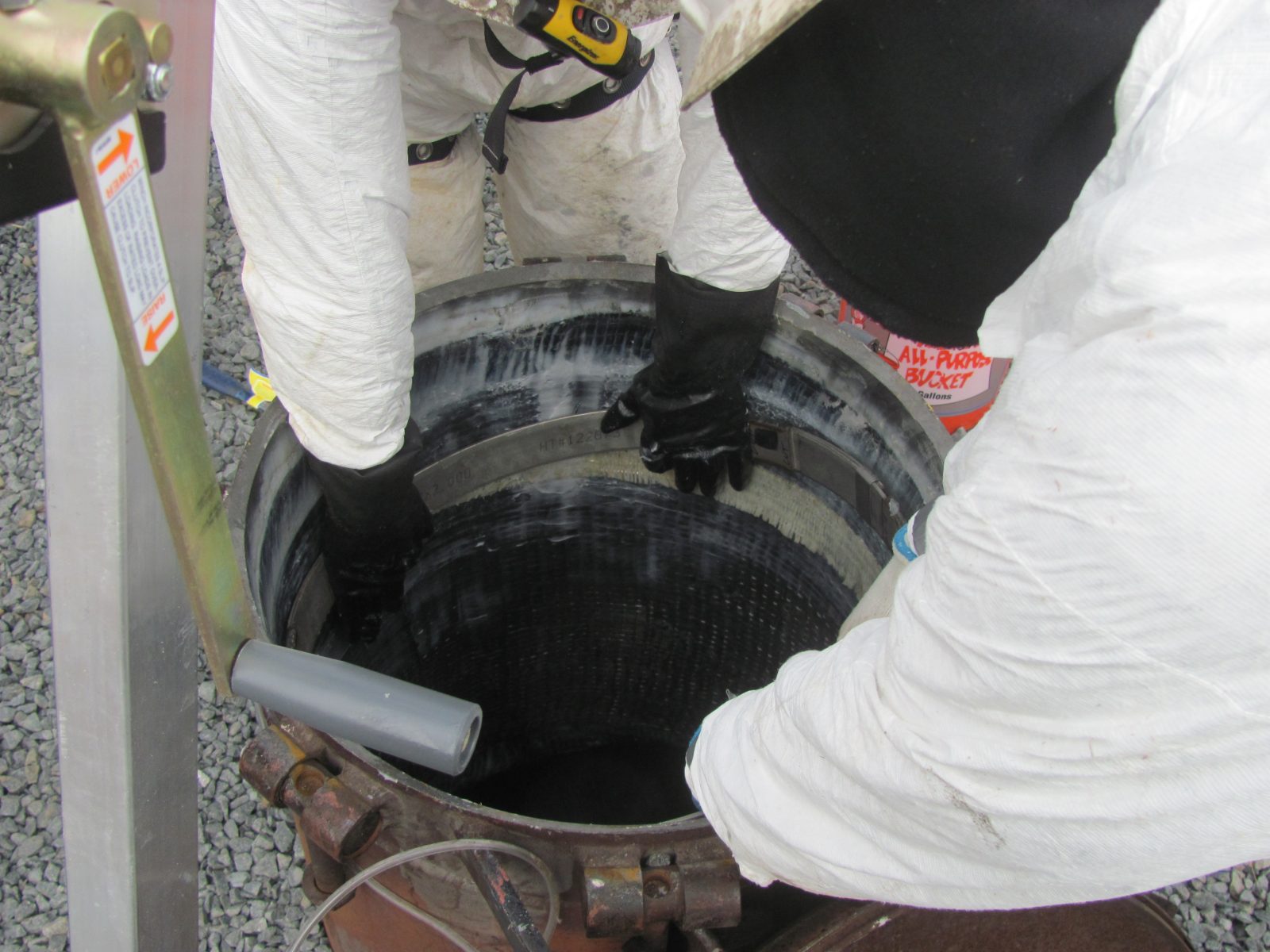

The low-pressure service water system comprises 36 in., 42 in., and 54 in. dia. steel pipe. Approximately 1800 ft of pipe was corroded and required repair. SGH designed internally bonded, carbon fiber-reinforced polymer (CFRP) repairs and provided engineering support during construction.

SGH designed repairs executed during planned outages. Highlights of our work include the following:

- Developed a three-dimensional finite element model of the entire repair area to determine the stresses in the CFRP-lined header

- Prepared drawings, calculations, and specifications, including procedures for preparing the surface, installing CFRP, and curing

- Performed continuous inspections during construction to verify compliance with repair design and specifications

- Conducted tension tests in our laboratory according to ASTM D3039 – Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials on coupons cut from CFRP test panels prepared during construction

- Provided a report summarizing all inspection and testing activities, including inspection of prepared surfaces, mockup testing for bond strength, inspection of preparation and installation of all materials, and post-installation inspection identifying defects and corrective actions as necessary

Project Summary

Solutions

Repair & Rehabilitation

Services

Structures | Advanced Analysis | Applied Science & Research

Markets

Science & Defense

Specialized Capabilities

Repair & Strengthening | Buried Infrastructure | Physical Testing

Key team members