Foxboro, MA

Gillette Stadium

Scope/Solutions

Gillette Stadium serves as home to the New England Patriots and the New England Revolution. The stadium has 68,000 seats on three decks, eighty luxury suites, and over 6,000 club seats. SGH consulted on several problems encountered during the final stages of construction.

Some of the items SGH consulted on include the following:

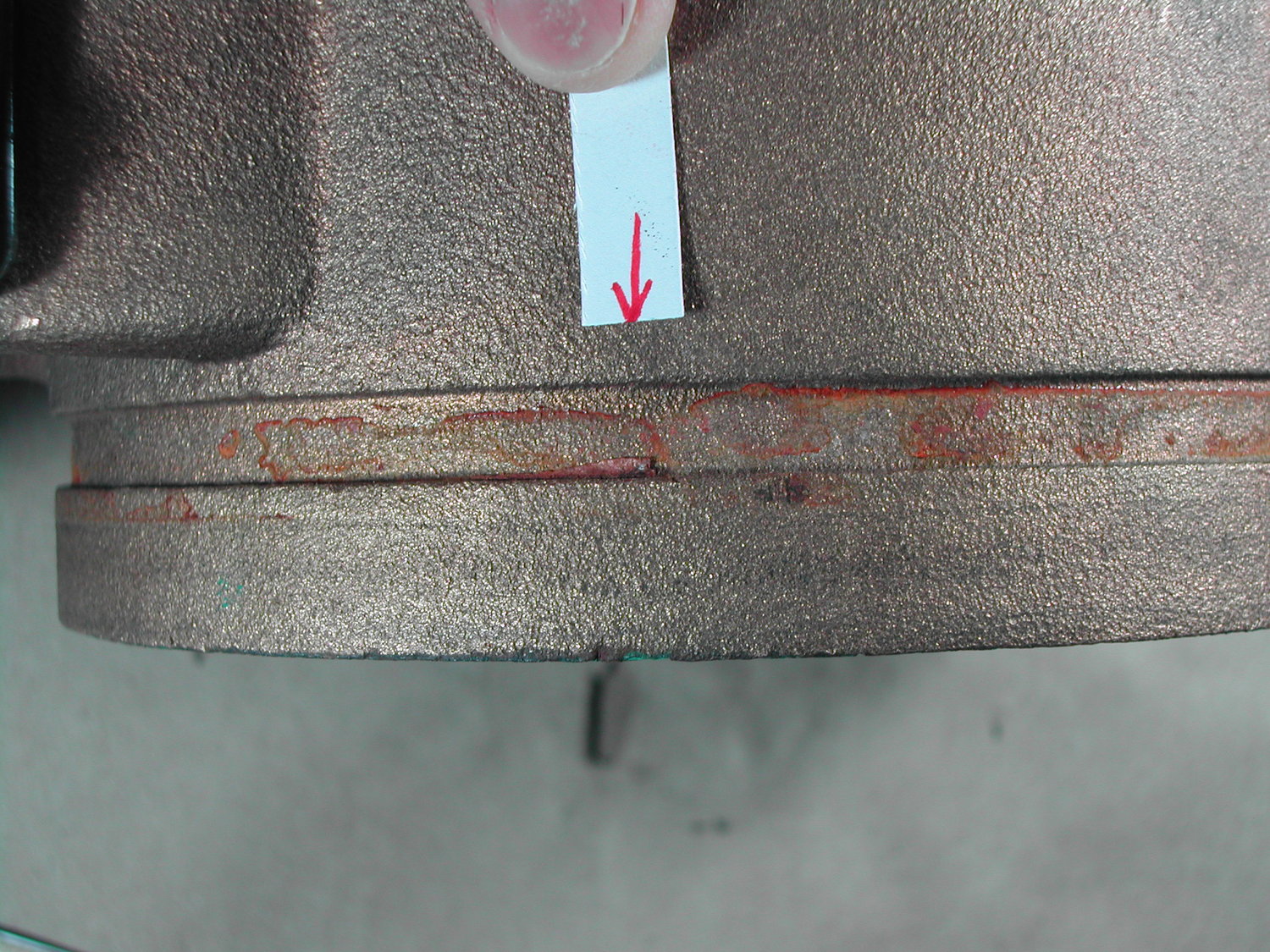

- Cracking and deterioration of structural precast concrete stadia units and their supporting beams

- Ponding throughout the stadium

- Strength of the curtain wall of the luxury suites to resist wind loads

- Leakage from expansion joints

- Cracked glass handrails

- Apparent mold growth in the curtain wall surrounding the concourse

- Valve joint failure in the pump-assisted high zone grey water system

Highlights of SGH’s work include the following:

- Surveyed structural stadia units using an onsite data capture system that helped streamline the investigation and report the extent of the problems to the owner

- Performed a petrographic examination of concrete in our laboratory to determine the causes of cracking and deterioration

- Evaluated construction tolerances to determine the cause of ponding on the stadia units

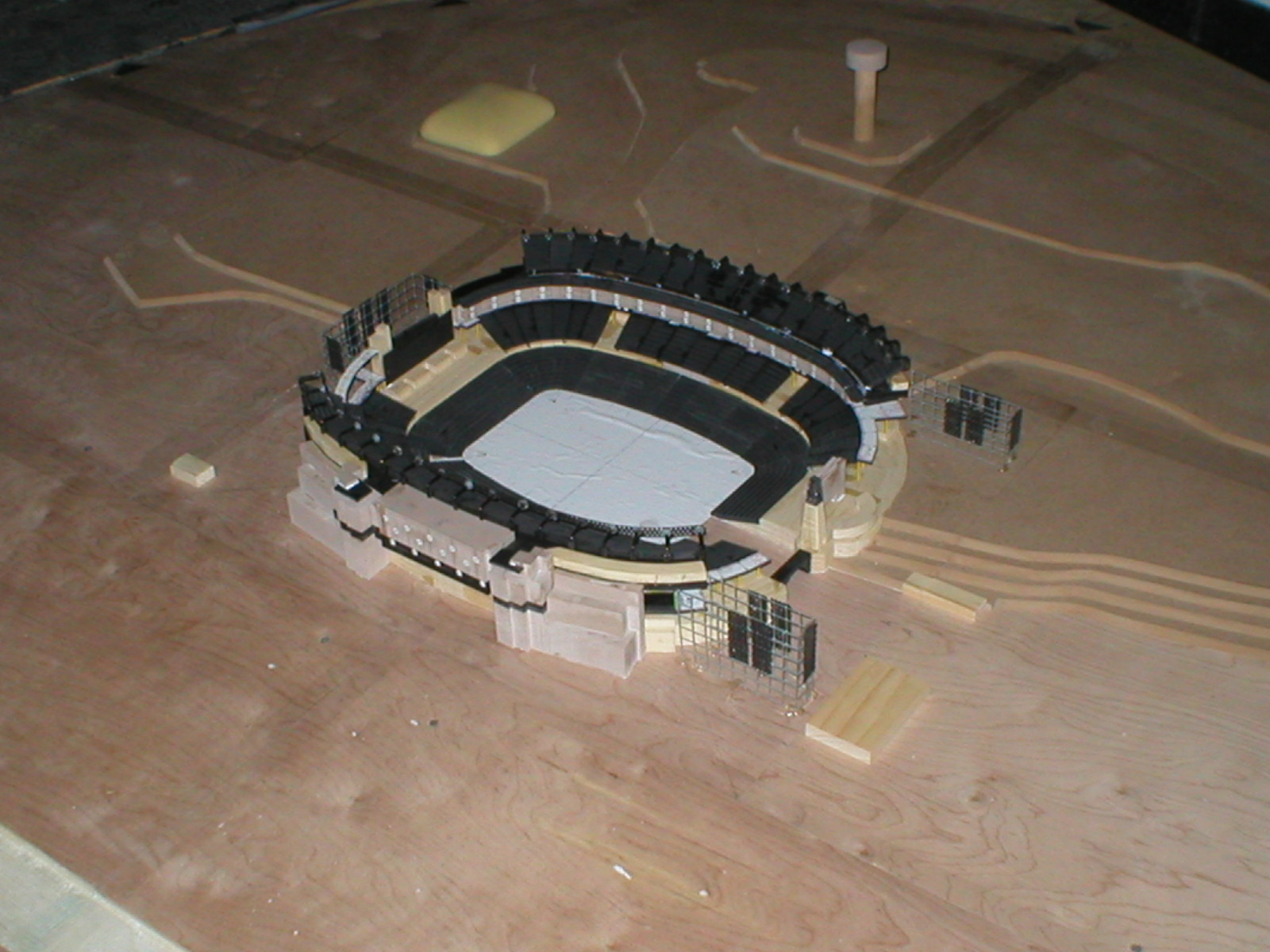

- Constructed a scale stadium model for a wind tunnel study to determine wind loads on luxury suite walls for comparison with design assumptions

- Monitored and evaluated grey water system operation, simulated testing of component failure, coordinated hydrodynamic analysis of the system, and determined the probable cause of the failure

1 of 7

Project Summary

Solutions

Failure Investigation

Services

Building Enclosures | Advanced Analysis | Structures | Applied Science & Research

Markets

Culture & Entertainment

Client(s)

Monahan & Associates PC | Goodwin Procter LLP

Specialized Capabilities

Repair & Strengthening | Roofing & Waterproofing | Failure Analysis | Materials Science | Microscopy

Key team members

Additional Projects

Northeast

National September 11 Memorial and Museum

The “bathtub” slurry wall at the World Trade Center (WTC) site survived when the WTC towers collapsed in 2001, making it a symbol of endurance. SGH evaluated, analyzed, and designed strengthening for a portion of the existing slurry wall.

Northeast

Clefs Moiré, One North of Boston

The interior installation, designed by Matt Trimble of Radlab, comprises two slatted walls using the moiré effect with segmented vertical ribbing. SGH provided structural engineering consulting services for the design of the walls.