Understanding Water Resistance Limitations of Fenestrations Under Severe Windstorm Conditions

How can my windows leak when they meet the building code? (And what can I do about it?)

Numerous tropical storms and hurricanes have struck the Gulf and Atlantic Coasts in recent years, with large storms such as Hurricanes Irma and Ian bringing heavy rains and gusting winds in wide swaths that can travel far inland. When this happens, the wind accompanying these storms may drive rain through fenestrations—such as exterior patio and balcony doors and operable windows often found in residential construction— that are intended to keep the weather out. Often these fenestrations admit wind-driven rain at wind speeds and wind-created pressures much lower than the windows are certified to resist structurally.

When this occurs, the resulting leakage can cause extensive water damage, leaving owners to wonder how their windows and doors can meet all relevant building code requirements yet still leak. This resulting mismatch in expectations, which we call the “expectation gap,” can lead to costly litigation and insurance claims demanding the replacement of windows that undoubtedly experienced leakage yet are undamaged. Understanding the strengths and vulnerabilities of various fenestration types can help narrow this expectation gap when selecting and specifying fenestration products.

The Expectation Gap: Structural and Impact Resistance Vs. Water Infiltration Resistance

Fenestrations are designed to resist structural loads based on design wind speeds found in the building code. In regions prone to windborne debris, the code may also dictate impact resistance. Code requirements are based primarily on protecting public safety and preventing catastrophic structural damage to the building by ensuring fenestrations and glazing remain in their openings under the specified wind pressures and missile impacts expected in the design-level storm.

However, the code does not explicitly specify resistance to wind-driven water intrusion. Instead, fenestration resistance to wind-driven rain for new products, by industry standards, defaults to a small fraction of the structural design pressure (typically 15% to 20%). This permits fenestrations that meet all aspects of the code but are still susceptible to substantial water leakage at pressures far below the structural resistance of the fenestration. Normal weathering and wear of internal and glazing seals and weatherstripping can also decrease the initial performance.

Comparing Structural Design Pressure to Default Water Infiltration Resistance

We illustrate the “expectation gap” below for a hypothetical site in Florida. First, we have arbitrarily selected an exposure category and building height to derive a structural design pressure required of the product (note that the design wind pressure we have derived will vary based on many variables, such as exposure category and building height). Next, we calculate the water infiltration pressure corresponding to the structural design pressure, as specified by industry standards and allowed by code. We then back-calculate the wind velocity that corresponds to the water infiltration pressure, without considering height or exposure category.

| Location: Fort Lauderdale, Florida |

| Nominal basic wind speed (Vasd): 132 mph (design-level storm) |

| Structural design wind pressure: 65lbs. per sq ft (psf) |

| Selecting a window with structural design pressure of 65 psf (DP65) satisfies the code, as it meets the 65 psf structural design pressure. |

| Industry default water resistance of DP65: 15% of 65 psf = 9.75 psf |

| Wind speed corresponding to 9.75 psf: 62 mph |

This example shows that the specified fenestration product may be susceptible to water intrusion at wind speeds above 62 mph, which is far lower than the 132 mph specified by the code for the design-level storm, hence our “expectation gap.” Furthermore, a storm generating the 62 mph leakage threshold pressure will occur far more frequently than a design-level storm.

Certain fenestration types, in particular sliding products that rely on a back dam or upturned leg at the rear of the sill (such as most hung and horizontal sliding windows and sliding doors), are typically more susceptible to leakage under severe wind conditions than out-swinging or fixed fenestration products. Products that rely on a back dam to resist water infiltration can fail when the applied wind pressure exceeds the water resistance of the back dam. Overtopping the back dam in this manner can result in severe, uncontrolled leakage. Given that one inch of back dam height can resist water penetration up to a pressure of 5.2 psf, a back dam would need to be greater than 12 in. in height to resist water infiltration in the design-level (65 psf) storm for our above example. Out-swinging, gasketed products, which rely on compression of gaskets rather than back dam height, tend to perform much better under severe conditions, and can typically achieve higher water penetration resistance levels and allow less water entry when they do leak. Inward wind pressure on these products typically causes additional compression that can contribute to watertight performance.

Strong storms are capable of causing water intrusion through fenestrations at wind pressures far lower than the pressures required to damage them.

Recognizing Severe Event Frequency

The basic wind speeds for structural design of buildings are published in ASCE 7, “Minimum Design Loads and Associated Criteria for Buildings and Other Structures.” Risk Category II buildings, which include most residential structures, specify basic wind speeds based on the probability of a 7% return rate in 50 years (700-year mean recurrence interval). Thus, the wind speeds used for structural design are based on rare, infrequent events.

A memorandum published in 2005 by the American Architectural Manufacturers Association (AAMA)—now the Fenestration & Glazing Industry Alliance (FGIA)—titled “Storm-Driven Rain Penetration of Windows and Doors” documents leakage concerns following severe events. The document states, “In the aftermath of tropical storms and hurricanes, questions have been raised by some residents who experienced wind-driven rain leaking through or around their windows and doors that otherwise remained unbroken and structurally intact during these extraordinary events.” This document confirms industry awareness of the “expectation gap” but attributes the occurrence of leakage to extraordinary events. However, as our example illustrates, wind pressures at 15% of ratings are common and may be increasing in prevalence due to climate change.

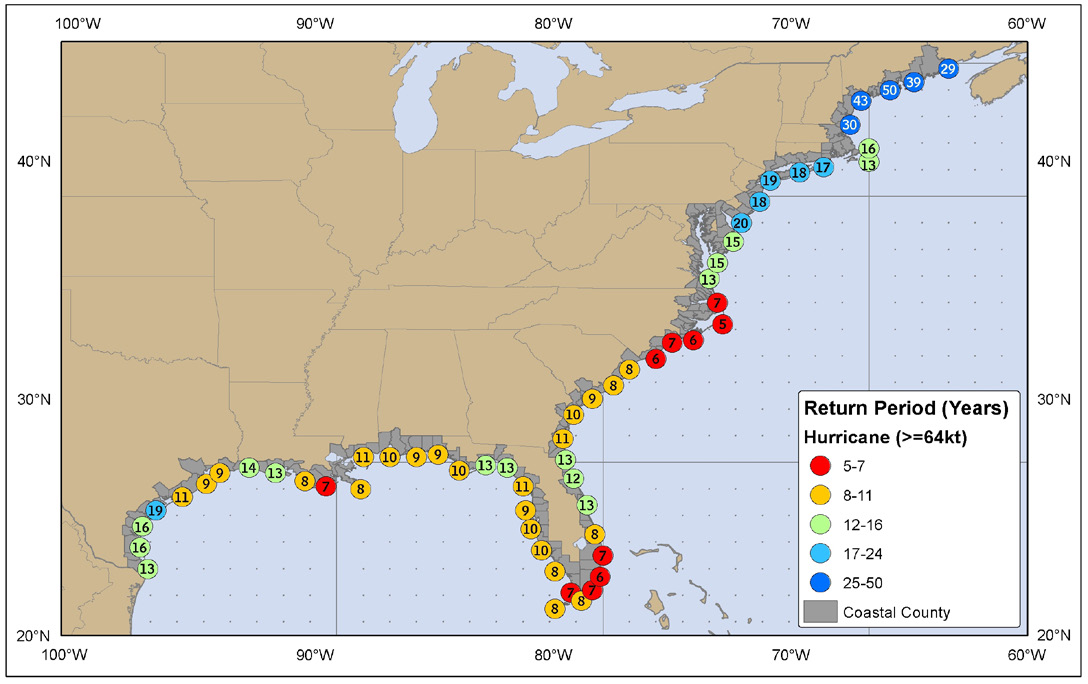

The figure below, published by the National Oceanic and Atmospheric Administration (NOAA), provides the average rate of return for hurricanes (wind speeds greater than 75 mph) in recent years. In much of the Southeast U.S., for example, a hurricane will return on average every 5 to 10 years, meaning windows and doors may see conditions capable of causing leakage on multiple occasions during their lifespan.

Hurricane return period, NOAA

Conclusion

Building codes require that fenestrations be designed to resist pressures and impacts to preserve the structural integrity of building enclosures. However, strong storms are capable of causing water intrusion through fenestrations at wind pressures far lower than the pressures required to damage them. Such storms are not “extraordinary” events, particularly in hurricane-prone areas of the Gulf and Atlantic Coasts. Rather, they can be expected to occur periodically over the life of the product. Fenestrations should be selected to reduce not only the risk of structural failure but also the risk of water infiltration under these periodic events. Further study— including probabilistic analysis of return intervals of periodic, strong (but not design-level) storms—may be helpful to establish new, higher fenestration performance levels with respect to water infiltration to better align with and manage this risk. In the meantime, window specifiers and purchasers should consider fenestration options like fixed windows, outswinging vents, and terrace (French) balcony doors that rely on continuous compression seals, and consider specifying higher, optional performance levels for water resistance.