Testing a First of its Kind: Applied Science & Research Protocols for Assessing Prototypes

Prototypes and first editions require robust testing to validate theoretical designs and analysis. Whether for an untested building material, novel assembly, or state-of-the-art industrial equipment, initial steps must be carefully considered and diligently tested by subject matter experts, applied scientists, and laboratory technicians to assess safety, evaluate concerns, and determine viability. Especially when it relates to mission-critical equipment or large-scale building systems, it can be challenging to introduce and justify innovative approaches to meet the needs of risk-averse owners, operators, and regulators.

However, the path to innovation is possible. Project and laboratory teams can follow four protocols to evaluate untested prototypes.

Develop a Testing Plan

To understand the unknown, laboratory teams validate innovative designs by asking critical questions: What happens to this substance when exposed to extended sunlight, water, cold, or heat? How will this structural connection perform under stress? Why have past iterations failed?

This questioning helps project teams develop and execute comprehensive testing and research plans to better understand materials, components, and systems. Together, engineers, scientists, and technicians identify project goals and develop testing protocols, which may include:

- Strong floor testing: Simulating pushing or pulling forces on large structural components.

- Mechanical testing: Conducting tension and compression loading, fatigue testing, etc.

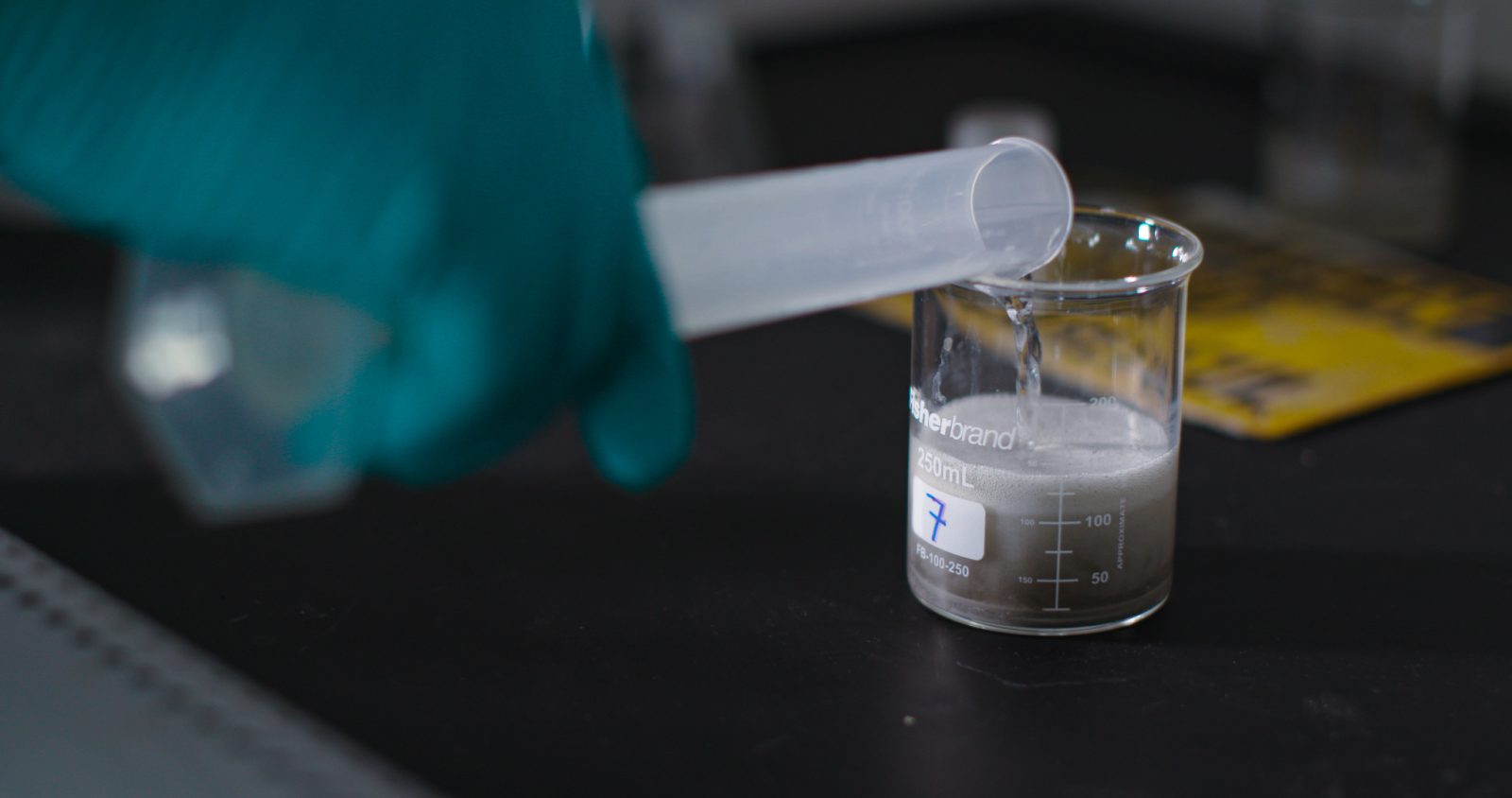

- Chemical and thermal testing: Investigating material compositions and properties.

- Microscopy: Performing microscopic examinations.

- Additional research: Providing academic and scientific institutions and other professional firms with the specialized expertise needed to analyze and validate results.

Create a Model, Sample, or Component

Given the first-of-its-kind nature of these types of projects, it is often necessary to build and recreate small- and large-scale versions of the prototype in question. This can include setting up custom test fixtures and operational methods that mimic the overall conditions that samples or equipment will be exposed to.

Any prototype inherently involves risk. Successful innovation helps to move our industry and society forward, but failure can lead to catastrophe.

Simulate Long-Term Exposure or Use

For untested prototypes, it is important to evaluate how materials, components, and systems will perform in specific environments to predict serviceability and suitability over longer time periods. Depending on the intended use, project teams can use a range of tools and simulation techniques to gain knowledge.

There is a wide range of testing equipment available, including:

- Walk-in freezers

- Environmental ovens

- Freeze/thaw cabinets

To simulate aggressive environments, evaluate long-term exposure, and replicate past events to efficiently determine the root causes of prior issues, laboratory technicians can use several techniques, including:

To simulate aggressive environments, evaluate long-term exposure, and replicate past events to efficiently determine the root causes of prior issues, laboratory technicians can use several techniques, including:

- Applying corrosive liquids

- Introducing high-temperature gases

- Exposing to ultraviolet light

- Spraying or flooding with water

Provide Confidence with Statistics

Using the results of the testing program, engineers, materials scientists, chemists, and laboratory technicians can use data to develop custom models to analyze special applications and circumstances. These computational mechanics approaches help to simulate and predict complex structural and material behavior and provide the statistical information needed for owners and operators to make informed decisions.

Models and test methods often must comply with—and be verified by—standards and procedures set forth by organizations, including:

- American Association for Laboratory Accreditation (A2LA) ISO 17025 standards

- American Association of State Highway and Transportation Officials (AASHTO)

- ASTM International (formerly known as the American Society for Testing and Materials)

- American Society of Mechanical Engineers (ASME) Nuclear Quality Assurance Program (NQA-1)

Case in Point: Nuclear Production Equipment Testing

SGH’s Applied Science & Research Center partnered with a cutting-edge radioactive isotope manufacturing company to evaluate equipment and components that are subjected to harsh conditions as part of the production process, including a new vacuum chamber that imposes continuous thermal cycles, alternately cooling gases to cryogenic temperatures then heating to elevated temperatures.

Following our defined protocols for this first-of-its-kind component, the project team:

- Developed a testing plan: For this novel equipment, SGH developed and executed a test to characterize thermal behavior and determine if all system components can withstand steady-state and transient thermal stresses to maintain confinement function of the materials.

- Created a model, sample, or component: SGH developed a custom test fixture and method that mimics the extreme thermal cycling conditions of the vacuum chamber.

- Simulated long-term exposure or use: A data acquisition program using multiple thermal detectors and position sensors helped quantify the prototype’s movement due to thermal changes as a function of temperature and time. This data will eventually be used for benchmarking and calibrating corresponding analytical models.

- Provided confidence with statistics: Given the nature of the radioactive materials to be used in the final product, all sensors were calibrated to the accuracy required to meet NQA-1 vendor standards and programmed to collect enough data to achieve high confidence in the results.

This ongoing project showcased the ability to solve novel problems with creative test solutions that provide clients with the information they need to improve their products.

Conclusion

Any prototype inherently involves risk. Successful innovation helps to move our industry and society forward, but failure can lead to catastrophe. It is understandable that today’s designers, construction managers, business owners, and operators may be reluctant to move forward with prototypes without stringent testing and analysis. Through a careful and thoughtful approach, and in collaboration with tested laboratory practitioners, it is possible to find pathways to advance with a degree of certainty.