Waltham, MA

Magnesium Oxide Board Research

Scope/Solutions

Replacing conventional building panel products with magnesium oxide (MgO) boards rose in 2020 as a response to issues with the materials supply chain. While the boards’ use peaked in the first half of the 20th century as a wood substitute in ship flooring, questions about their effects on corrosion, combustibility, and quality control had diminished their use. SGH conducted internal research to investigate the material properties of MgO boards to help us evaluate them for future projects.

Our testing program included boards from three manufacturers with varying composition, including two primarily composed of magnesium oxysulfate cement and one made with magnesium oxychloride cement. Highlights of our work include:

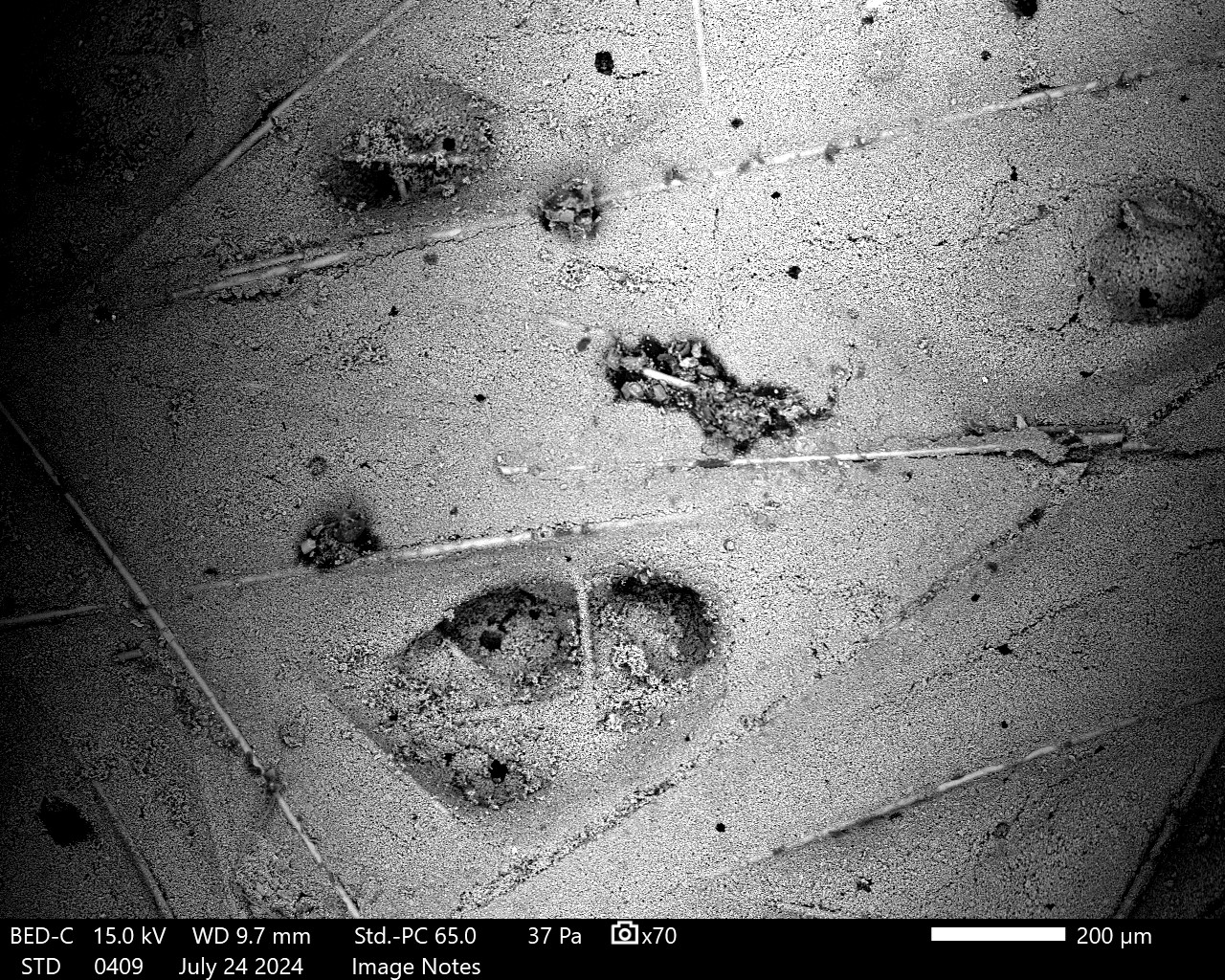

- Identifying the boards’ construction and material constituents

- Documenting known differences between magnesium oxysulfate cement and magnesium oxychloride cement

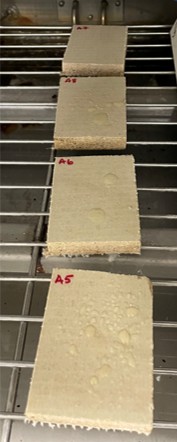

- Measuring water absorption and thickness swelling based on the procedures outlined in ASTM D1037 – Standard Test Methods for Evaluating Properties of Wood-Base Fiber and Particle Panel Materials

- Performing water vapor transmission testing based on ASTM E96 – Standard Test Methods for Gravimetric Determination of Water Vapor Transmission Rate of Materials

- Observing the panels after exposures to repeated freeze/thaw cycles and conditioning at high temperatures/high relative humidity

- Measuring the chloride content in board sweat and in the solid boards

- Documenting corrosion on embedded fasteners after exposure to high humidity

- Conducting flexural testing of the boards

Project Summary

Solutions

Evaluation

Services

Applied Science & Research

Key team members