Salt Lake City, UT

Bingham Canyon Mine

Scope/Solutions

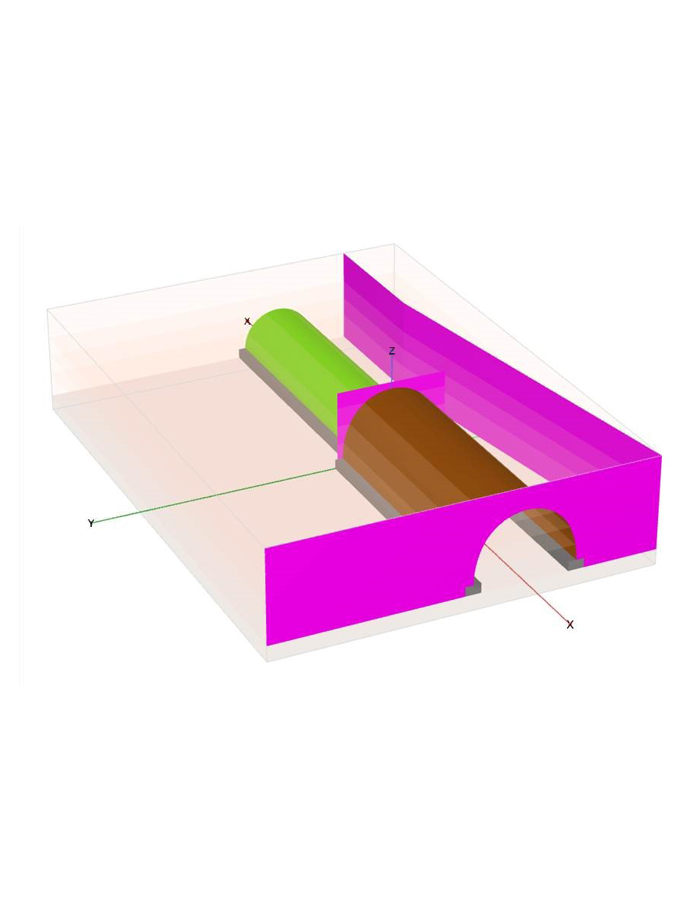

A conveyor belt runs along one of the canyon benches at the copper mine. The upper slope of the canyon was undergoing a slow and predictable landslide transverse to the conveyor belt. To protect the conveyor belt from falling debris due to the potential slope collapse, the mine operator built a corrugated steel arch tunnel embedded within a mechanically stabilized earth (MSE) wall. SGH evaluated the tunnel structure and helped the mine operator establish a monitoring program to identify when the tunnel exceeded its ability to support additional load.

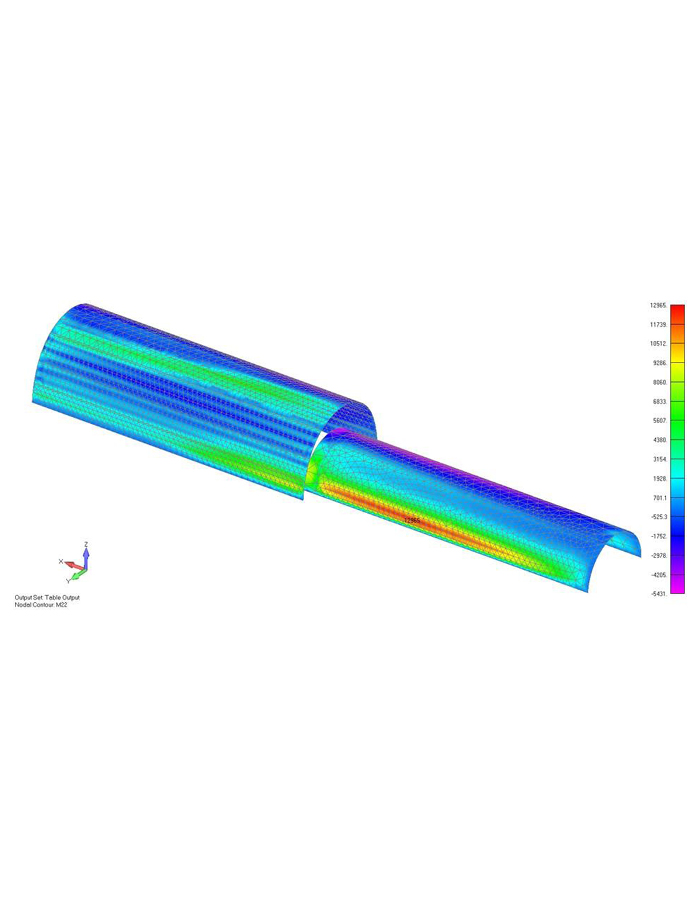

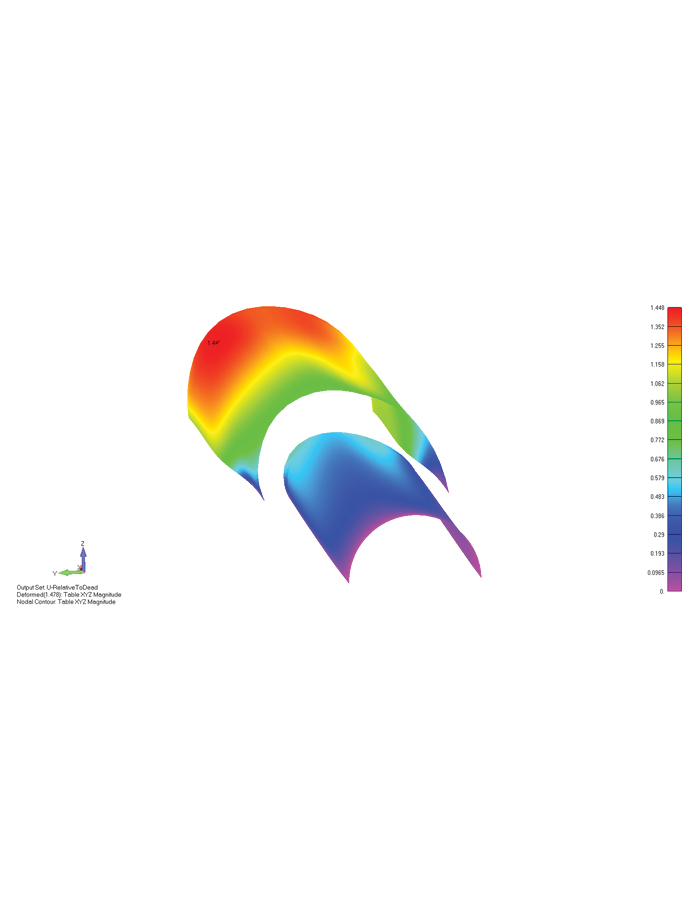

SGH visited the site to document the as-built construction and reviewed documentation related to site geometry and geotechnical properties. We performed three-dimensional, soil-structure interaction finite element analyses to determine the tunnel shape due to ground movement and correlated deformation to the tunnel’s stress.

By conducting periodic inspections of the tunnel’s movement, the mine operator was able to compare the measured shape with SGH’s analysis results, allowing them to evaluate the stability of the tunnel and ensure safe operations at their site.

Project Summary

Key team members